Metalex has the widest range of expanded metal products in the industry.

Expanded metal is an extremely versatile material. It is available in a wide variety of ferrous and non-ferrous metals, as well as a wide range of mesh sizes.

Although there are standard designs, what makes our process so versatile is the pattern variations you can choose from. These patterns can be specified to achieve whatever characteristics are most critical for your specific applications.

When selecting expanded metals, there are many considerations to keep in mind. For instance, increased pattern size alters the open area and improves cost-effectiveness, while varied strand width changes both the appearance and weight.

Did you know that Metalex not only offers the highest quality expanded products available, but also the widest range of these products in the industry?

This is largely due to our extensive experience in this industry for over five decades—we have continued to develop our brand throughout our lengthy tenure. Our selection includes:| Light and Small Mesh | Intermediate Mesh |

| Micro Mesh | Large, Heavy & Grating Mesh |

Our design and engineering teams are experts in regards to this highly versatile material. Not only can we teach you everything there is to know about expanded metal, we can also work closely with you to offer practical recommendations and solutions that are specific to your needs.

Types of Expanded Metal

Available in Coil, Sheet or Custom Blank

Metalex’s variety of sizes, patterns and manufacturing capabilities ensure expanded metal solutions for virtually any application. We offer light and small meshes, intermediate meshes, large, heavy and grating meshes, micro meshes, and others. In addition, products are available in coils, sheets or custom blanks.

How Is Expanded Metal Made?

Process

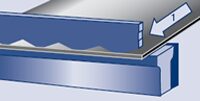

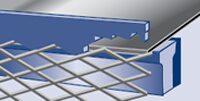

Expanded metal converts solid sheet or plate metals into a material with diamond-shaped openings joined by continuous, uniform strands. The simultaneous slitting and stretching process generates an expanded material with essentially no scrap. The result is a strong, structurally sound, no-raveling metal product that permits the passage of heat, fluids, light, sound, and air.

Although there are standard designs, expanded metal is almost infinitely variable in pattern and can be specified to achieve whatever characteristics are most critical.

- Increased pattern size improves cost-effectiveness.

- Varied strand width changes appearance and weight.

- Unflattened expanded metal provides strength and rigidity.

- Flattening smoothes the surface. Versatile and functional, expanded metal becomes an economical component in many designs. Its ability to be engineered to specific applications yields a product uniquely suited to its end use.

No Scrap, No Raveling

These are the advantages that set expanded metal apart from either perforated metal or wire cloth, making it both more economical and easier to handle.

Step 1. Sheet or plate is advanced beyond the face of the bottom die in an amount equal to the strand width before flattening. The sheets are then fed into an expanding machine.

Step 2. The top die then descends and simultaneously slits and cold forms an entire row of half diamonds.

Step 3. The top die then ascends and moves one half of a diamond to the right as the base sheet or plate moves forward one strand width.

Step 4. The top die descends, slits and forms another full row of half-diamonds completing a row of full diamonds in two strokes.

Step 5. The die then ascends and returns to its initial position.

Benefits of Expanded Metal

Compared to traditional sheet metal and other material options, expanded metal offers many advantages. Some of the key benefits include:

Greater cost-effectiveness and material efficiency.

The expansion process turns a small quantity of metal into a large sheet, which reduces the amount of material needed to fulfill an order and, therefore, the material cost. Additionally, the process produces little to no material waste.

Better conductivity.

As expanded metal is made from a single continuous sheet, it is far superior at conducting electricity, magnetic flux, and heat than assembled sheet metal.

Higher strength and stability.

Expanded metal retains much of the base metal’s strength and, compared to woven or welded metals, offers better load carrying capacities and stress resistance. Additionally, it can be reinforced with glass, concrete, or other materials for even greater strength and stability.

Lighter material weight.

Since expanded metal features cut and stretched holes, it is much lighter than similarly sized solid sheet metal.

Easier workability.

Expanded metal readily accommodates cutting, forming, and shaping operations.

Broader range of performance characteristics.

Expanded metal demonstrates many advantageous properties that suit it for use in different applications. For example, it allows air and light to flow through freely, it can be used to help or hinder acoustic transfer, and it can have different finishes, such as anti-slip or non-skid, to accommodate different facility needs.

Applications of Expanded Metal

|  |  |

Whatever the pattern or requirements, below is a list of some of the many applications for which this is ideal:

- Park & Recreation

- Patio furniture

- Car grilles

- Lockers

- Machine guards

- Automotive racks

- Chimney caps

- Shelving

- Ceiling panels

- Trailer flooring

- Waste receptacles

- Catwalks & stairs

- Animal flooring

- Screening

- Vents

- Architectural applications

- Speaker grilles

- Airbags

Expanded Metal Solutions From Metalex

Did you know that Metalex not only offers the highest quality expanded products available, but also the widest range of these products in the industry? This is largely due to our extensive experience in this industry for over five decades—we have continued to develop our brand throughout our lengthy tenure.

Our design and engineering teams are experts with regard to this highly versatile material. Not only can we teach you everything there is to know about expanded metal, but we can also work closely with you to offer practical recommendations and solutions that are specific to your needs.

To learn more about expanded metal or discuss your specific project, contact the experts at Metalex today. For ordering information please visit our expanded metal ordering page.