Standard Expanded Metal vs. Flattened Expanded Metal

Comments Off on Standard Expanded Metal vs. Flattened Expanded MetalExpanded metal—i.e., sheet metal that is cut and stretched to form a generally diamond-shaped pattern—finds application in numerous industries, ranging in use from consumer products to construction projects. It is available in many variations, each of which features different sizes, strand widths, and patterns to suit different needs. In addition to determining the above design elements, when choosing expanded metal for an operation, it is important to consider whether standard or flattened expanded metal is more appropriate.

The following article outlines the differences between flattened and standard expanded metal to facilitate the decision-making process.

All About Standard Expanded Metal

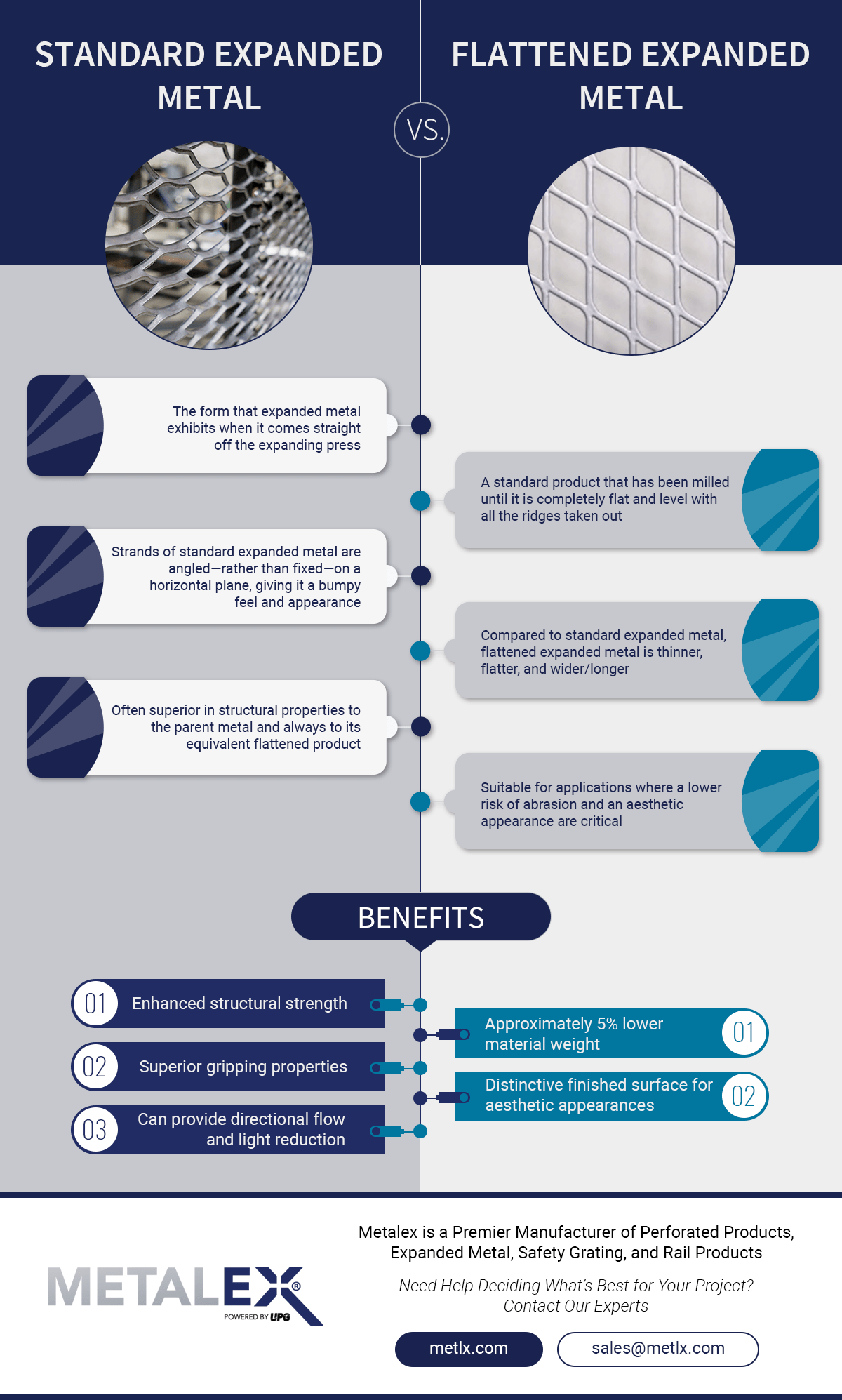

All About Standard Expanded MetalAs the name implies, standard expanded metal is the form that expanded metal exhibits when it comes straight off the expanding press.

The strands of standard expanded metal are angled—rather than fixed—on a horizontal plane, which makes the material less smooth than its flattened counterpart.

The particular characteristics exhibited by a sheet of standard expanded metal are largely determined by the amount of expansion applied, the pattern size, and base sheet thickness. However, in general, the uneven surface offers enhanced structural strength and better gripping properties. Depending on the pattern design, the material can also be used to direct the flow of light, air, fluids, and solid materials.

All About Flattened Expanded Metal

Flattened expanded metal begins as standard expanded metal but is then subjected to milling processes that smooth the horizontal surface.

These processes remove the ridges characteristic of standard expanded metal, producing a flatter and smoother surface.

Compared to standard expanded metal, flattened expanded metal is thinner, flatter, and wider/longer, which translates to approximately 5% lower material weight. This characteristic, combined with the finished surface, makes it suitable for applications where a lower risk of abrasion and an aesthetic appearance are critical.

The exact dimensions of flattened expanded sheets depend on how the material passes through the rolled—i.e., short way of design (SWD) or long way of design (LWD)—and can vary from one expansion operation to the next. Both of these qualifiers make it difficult to estimate the exact size and pattern of a finished sheet.

Expanded Metal Solutions From Metalex

Expanded metal is a highly versatile material that can be manufactured to meet the requirements and restrictions of many industrial applications. It is available in a variety of base metals—both ferrous and non-ferrous—and in numerous different mesh sizes, patterns, and finishes.

At Metalex, we pride ourselves on providing the highest quality expanded metal solutions—in standard and flattened variations—in the industry. Whether you require industrial grates, construction mesh, etc., we have the materials to make any expanded metal project a success. Armed with decades of industry experience, our expert design and engineering teams are knowledgeable in all things expanded metal, enabling them to provide informed material recommendations and solutions for any customer need.

For additional information about our expanded metal products and services or assistance with an upcoming project, contact the experts at Metalex today.