- Metalex Safety Grating

- Safety Grating Applications

- Industries that Use Safety Grating

- Work With Metalex

Metalex offers a range of safety grating products to help you create a safer work environment.

Combining years of manufacturing experience and proven performance, Metalex delivers safety grating products that are among the best available on the market. At Metalex, we now proudly offer our clients the highest quality safety grating, helping to ensure safety in the workplace.

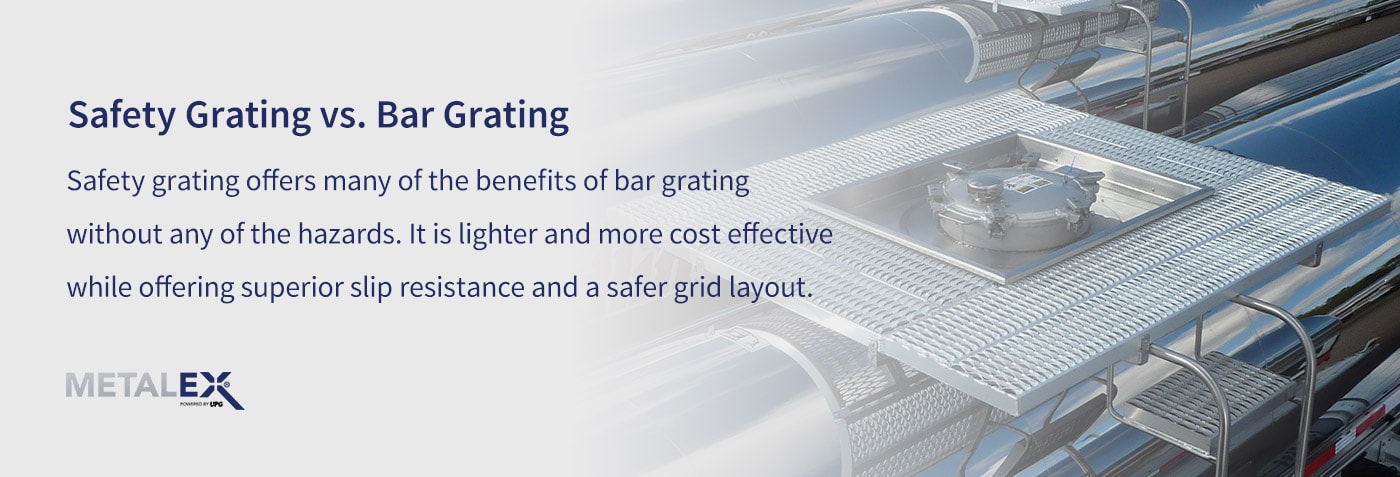

At Metalex, we understand that a safe work environment cannot be compromised. Our exceptional metal products help prevent slips and falls in and around plants and on OEM equipment. In addition, safety grating’s lightweight structure and various patterns provide a superior alternative to bar grating.

Our proven safety grating products have been counted on since 1903, and offer unmatched quality and value and performance. They include:

Open Grip® Safety Grating

Metalex Open Grip® is the original round hole debossed grating, and has been widely used in a variety of industrial applications for many years. It is used wherever safe, comfortable, slip-resistant footing on open flooring is necessary.

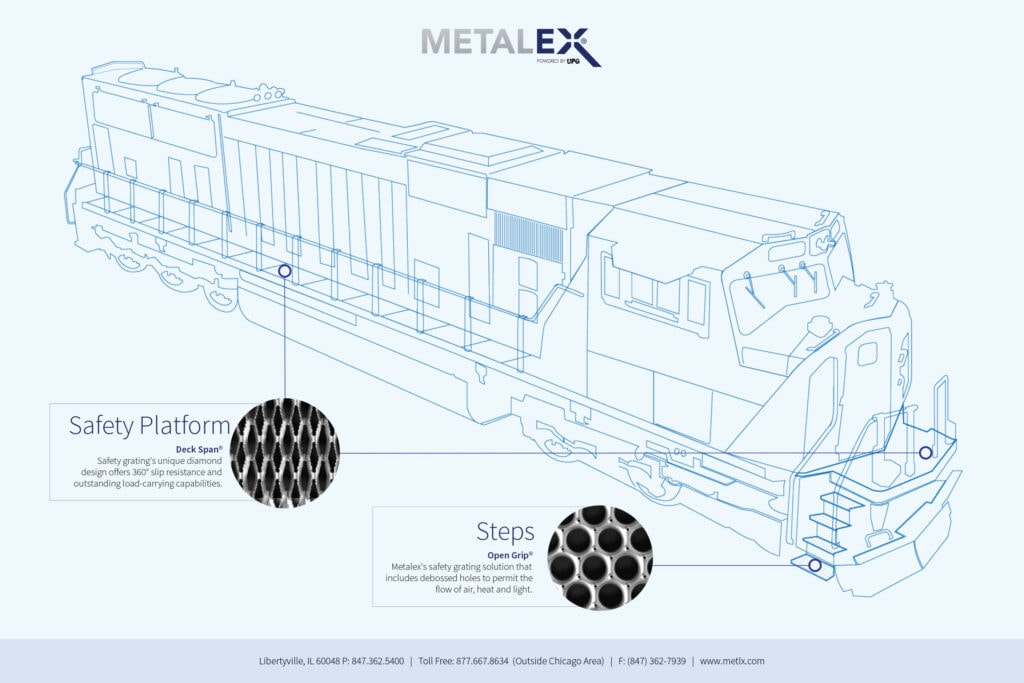

The self-cleaning Open Grip® is produced by a cold-working process that creates raised, perforated buttons and 1-3/8″ debossed holes that permit the flow of air, heat, and light. The circular gripping buttons of Open Grip® are user-friendly, retain their slip resistance with wear, and provide excellent slip resistance in all directions.

Deck Span® Safety Grating

Metalex Deck Span® grating features a unique, one-piece construction that is self-framing and lightweight, while offering outstanding load-carrying capabilities. Deck Span® grating products provide in-plant safety in the form of open flooring, catwalks, platforms, balconies, stair treads, and walkways.

The surface pattern is a unique diamond configuration created by the cross-hatching of formed and reticulated metal struts, which allows for the passage of light and waste materials. The diamond design offers slip resistance in all directions. Deck Span® has a relief hole at the point of the diamond, helping to prevent any cracking that may occur due to stress.

Learn More

Tread Grip® Flooring

Another exceptional safety product unique to Metalex, our Tread Grip® is metal flooring with an important difference: a surface of closely-spaced perforated buttons produced by cold forming. Tread Grip® is most frequently used over existing flooring and for indoor applications. Its circular tread pattern provides high-adhesive friction and long service life, making it ideal for many different applications.

Star Deck Safety Grating

Star Deck safety grating is a highly slip-resistant, low-profile metal grating. The star-shaped holes offer 360° slip resistance and is commonly used on heavy equipment platforms and steps.

Metalex’s unique process allows for countless pattern possibilities. Standard size is 11 gauge, hot rolled, 48″ x 100″. Custom sizes, finishes and gauges are also available.

Applications of Industrial Safety Gratings

Industrial safety gratings improve working conditions—facilitating compliance with health and safety regulations—for a variety of workplaces and worksites. They find use in a wide range of industrial applications, including the following:

Walkways

In the industrial sector, the term “walkway” can refer to overhead walkways (i.e., catwalks), rooftop walkways, or pedestrian walkways. Integrating safety gratings into any of them translates to significant benefits for their users. For example:

- In catwalks, safety gratings serve as lightweight and economical flooring components with minimal maintenance requirements. They improve safety conditions for employees using the walkway by mitigating the risk of slipping due to the presence of ice, moisture, and oil accumulation. In large facilities, they facilitate better lighting conditions as the holes in the individual grating sections allow light to pass through relatively unobstructed.

- In rooftop walkways, the exterior walking surfaces are susceptible to the buildup of ice, chemical film, mud, and other slick substances. The design of safety gratings allows these compounds—in solid, liquid, and gaseous form—to easily fall through the holes, facilitating cleaning and maintenance operations. This quality makes it easier to establish well-defined and safe walking paths for workers.

- In pedestrian walkways, safety gratings help create safe, temporary and permanent walking paths in a wide range of public spaces, such as streets, gardens, and ports. The perforated or expanded metal components facilitate the ventilation of air and water, which ensures safer conditions for both walking and vehicle-assisted pedestrians, including those with high heels, wheelchairs, strollers, scooters, and skateboards.

Ladders

Ladders allow workers to reach elevated areas in indoor and outdoor environments. The risk of injury to life and limb at these higher elevations increases with the addition of substances that can induce slipping, such as water, ice, and grime. Safety grating is ideal for use in these situations as the versatile material provides slip resistance across a wide range of environmental conditions. In the OEM sector, safety grating commonly finds application in the ladder rungs of tanker trucks and work trucks.

Stair Treads

When integrated as stair treads, safety grating provides a strong, aesthetic, and non-slip surface for workers to walk up and down safely. The material serves as a cost-effective solution for a variety of environments, including architectural stairs and the steps of vehicles such as work trucks, semi-trucks, and trains. In the latter, their durability allows them to withstand the harsh conditions experienced on the road without loss of their integrity.

Work Platforms

Work platforms allow workers to perform operations at elevated heights in various indoor and outdoor locations, including construction sites, manufacturing factories, and processing facilities. Similar to catwalks and ladders, these structures carry a higher risk of injury due to slips and falls, especially when exposed to slip-inducing substances such as ice or water. Using safety grating in them, as in the others, decreases the likelihood of slipping (as the accumulation of slippery compounds is reduced) and increases worker visibility (as lighting conditions are improved).

Transportation Servicing Areas

Outdoor transportation servicing areas are highly trafficked locations. Their regular exposure to the elements and vehicle fluids increases the risk of slipping and other related accidents for the people who use them. Safety gratings offer strength, durability, and slip resistance for the various surfaces in these areas, including work platforms, walkways, and ladders.

Ramps

A ramp is a simple machine that enables workers to transport materials to and from locations at different elevations easily, such as from the loading dock to the transportation vehicle or vice versa. Using safety grating on a ramp provides greater slip resistance—which decreases the risk of accidents during loading and unloading—and lower construction and maintenance requirements—which increases the cost-effectiveness of the particular structure. Typical locations of ramps that employ safety grating include docks, freight stations, industrial plants, and warehouses.

Flooring

As safety grating provides superior slip resistance compared to less durable alternatives, it is ideal for use as flooring in many industrial environments. When used as flooring, the material commonly finds application in the manufacture of truck trailers and aircraft group support equipment.

Channels

Channels play a functional and decorative role in many industrial machines, systems, and structures. Ones made from safety are particularly well-suited for demanding industrial environments, such as in OEM products and aircraft ground support equipment.

Running Boards

Running boards are stepping surfaces that facilitate entering or exiting a vehicle, such as a truck or train. Employing safety gratings in the manufacture of these components allows industry professionals to achieve greater durability and slip resistance in the finished units for break steps, crossovers, and end platforms.

Ready to Get Started?

Industries Served by Industrial Safety Gratings

At Morton, our safety gratings create safer working conditions across a variety of industrial environments. Some of the industries that benefit from using our products in the construction of their walkways, ladders, stairs, ramps, and more include the following:

Construction

For architectural applications, perforated and expanded metal grating offers a number of advantages. The material provides greater strength, reliability, and flexibility, qualities that make it well-suited for use in critical structures, such as stairs, ducting, roofing, and more.

Agriculture

In the agricultural sector, safety grating serves many functions. In addition to fostering safer working conditions by reducing the accumulation of slip-inducing substances, the material promotes optimal drying conditions for grain processing and storage operations.

Mining

Equipment and systems employed in mining operations are regularly subjected to harsh conditions, including extreme weather, corrosive compound exposure, and impact from debris. Our safety grating products demonstrate the strength and durability to withstand these conditions, providing reliable long-term performance. Some of our products that are particularly well-suited for use in mining environments include:

- Open Grip® metal safety grating.The design’s cold-formed raised buttons and debossed holes allow dirt and debris to fall through, ensuring a clear and clean walking path.

- Deck Span® metal safety grating.The design features superior slip resistance, a quality ideal for stair treads, ladders, and other walking surfaces.

Crane

Similar to catwalks, ladders, and work platforms, cranes carry a higher risk of worker injury from slips and falls due to their elevated working conditions. Our safety grating provides a lightweight but durable surface that reduces the risk of slipping. It is suitable for use in many crane components, including the stairs, walkway, and operating platform.

Ground Support/Communications

The growing popularity of electronic communications necessitates the expansion of telecom networks. This need, in turn, demands the erection of additional communication towers. For these structures, telecom companies are increasingly using safety grating in new constructions, both to improve safety conditions for workers and protect sensitive equipment.

Trucking

Safety grating is used for many truck body components, including steps, flooring, and work platforms. The material offers durability and slip resistance—even when exposed to harsh road conditions, such as rain, snow, sleet, and dust—qualities that help ensure the safety of workers during loading and unloading operations.

Contact the Experts at Metalex for Safety Gratings

At Metalex, we specialize in high-quality expanded and perforated metal product solutions, including safety grating. Equipped with over 50 years of collective experience working with safety grating, our expert team has the knowledge and skills required to help you identify the ideal safety grating product for your project’s needs.

To find out more about safety grating, download our eBook, The Benefits of Safety Grating Over Similar Options. For additional information about our safety grating offerings or assistance choosing a solution for your application, contact us or request a quote today. One of our experts will answer and address any questions or concerns you may have.

To find out more about safety grating, download our eBook, The Benefits of Safety Grating Over Similar Options. For additional information about our safety grating offerings or assistance choosing a solution for your application, contact us or request a quote today. One of our experts will answer and address any questions or concerns you may have.