Perforated Metals & Products Manufacturing from Metalex

At Metalex, we are rapidly and regularly growing our offerings of perforated materials. We strive to provide our clients with a quality product that meets their constantly evolving needs.

As our clients’ needs grow, so too does our selection of perforated patterns and materials. In addition to industry standard patterns and sheet sizes, we also offer advanced capabilities.

Whether your perforated metal needs are simple or complex, our experienced sales and engineering team has the technical expertise to ensure you get the exact product for your application and requirements; you’ll get the ideal product the first time, and each subsequent time you choose Metalex.

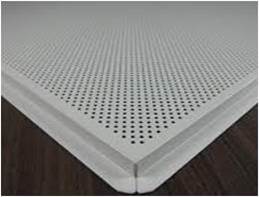

What is Perforated Metal?

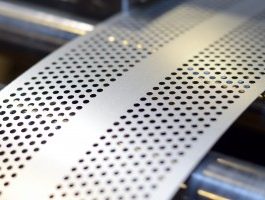

Perforated metal is manufactured by using punches or presses to create a series of holes, slots, bars, or decorative patterns in sheet metal. In earlier times, these sheets would have to be designed by skilled laborers using manual hand tools, but thanks to advancements in modern technology, perforated sheet metal can be produced using a variety of machining methods.

Perforated metal is manufactured by using punches or presses to create a series of holes, slots, bars, or decorative patterns in sheet metal. In earlier times, these sheets would have to be designed by skilled laborers using manual hand tools, but thanks to advancements in modern technology, perforated sheet metal can be produced using a variety of machining methods.

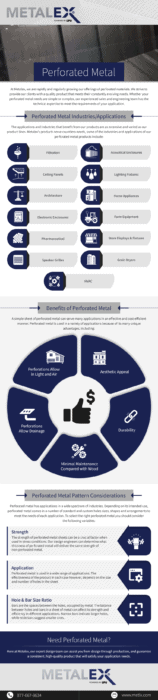

Perforated Metal Applications

The applications and industries that benefit from our products are as extensive and varied as our product lines. From construction and pharmaceutical applications to filtration and a host of other industrial uses, Metalex’s perforated products serve countless needs. Industries and applications of our products include:

- Filtration

- Acoustical Enclosures

- Ceiling Panels

- Lighting Fixtures

- Architecture

- Home Appliances

- Electronic Enclosures

- Farm Equipment

- Pharmaceutical

- Store Displays & Fixtures

- Speaker Grilles

- Grain Dryers

- HVAC

|  |  |

Material Options

Metalex specializes in the manufacturing of perforated products utilizing a number of materials. As numerous as the applications and industries that rely on perforated products are, so too are the materials from which our products can be made. These include the following, though we can also work with a number of different types of plastics and metals not listed below.

- Tinplate

- Galvanized Steel

- Stainless Steel

- Brass

- Aluminum

- Cold Rolled Steel

- Copper

- Monel

- Inconel

- Titanium

- Most Formable Metals

- Wide Variety of Plastics

- Certain Composites

Perforated Metal Patterns

In addition to offering products of varied materials, Metalex offers industry standards and specials for perforated metal patterns. Of course, the most ideal pattern will depend on the intended application and requirements of your project, as well as on factors such as strength, distribution of holes and bars, and more. At Metalex, our experts can guide you to the right pattern to accompany your chosen material.

At Metalex, we pride ourselves on being able to anticipate and respond to the rapidly evolving needs of our clients by providing them with a robust and comprehensive product offering. To give our clients the most options possible, we offer industry-standard patterns and sheet sizes, as well as advanced capabilities.