Grain Drying and Storage | Specialty Industries Highlight

Comments Off on Grain Drying and Storage | Specialty Industries HighlightSafety Grating in Grain Drying and Storage Applications

A wide range of industries and applications make use of safety grating to enhance personnel safety and ensure smooth, efficient operations. In the agricultural sector, for instance, grain drying and storage operations make frequent use of safety grating, as workers must be adequately protected on any walkways exposed to the elements. In these scenarios, grating must be able to perform even in wet or icy conditions. In addition to protecting worker safety, use of proper metal grating can help ensure optimal drying — keeping grain safe from moisture while reducing the risk of extra expenditures and downtime.

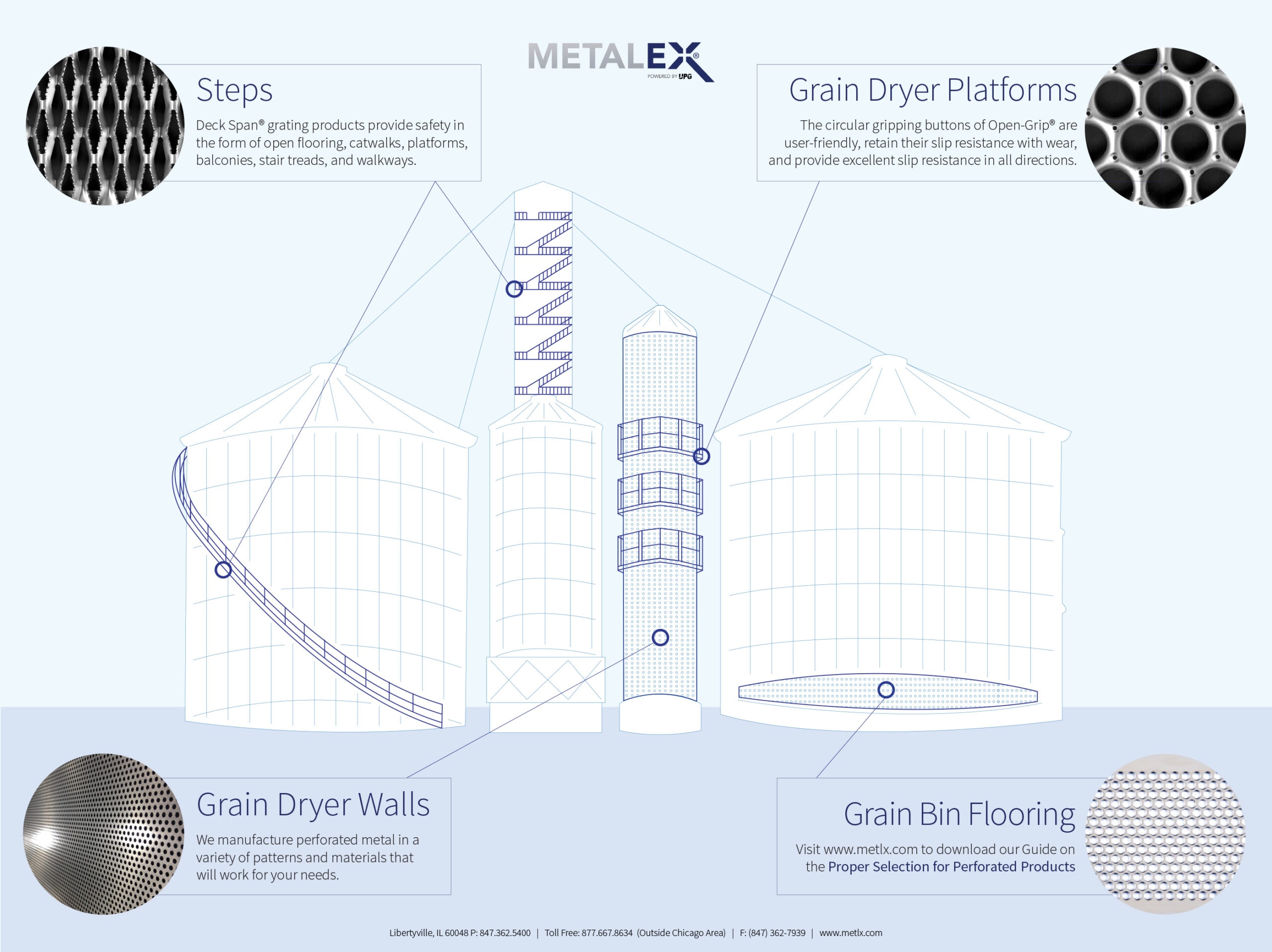

A wide range of industries and applications make use of safety grating to enhance personnel safety and ensure smooth, efficient operations. In the agricultural sector, for instance, grain drying and storage operations make frequent use of safety grating, as workers must be adequately protected on any walkways exposed to the elements. In these scenarios, grating must be able to perform even in wet or icy conditions. In addition to protecting worker safety, use of proper metal grating can help ensure optimal drying — keeping grain safe from moisture while reducing the risk of extra expenditures and downtime.At Metalex, we’re proud to offer our proprietary Deck Span® safety grating, providing peace of mind for workers in potentially dangerous grain drying and storage scenarios. Extremely versatile, this grating can be manufactured for use on catwalks, platforms, balconies, stair treads, and walkways.

Safety Grating in Action

In addition to grain drying, various other operations require safety grating to ensure adequate worker safety, preventing company liability and providing all employees with the confidence they need to get the job done. Below are three areas that can benefit from Metalex’s safety grating products.

—Grain drying and storage — As mentioned earlier, personnel must often traverse exposed walkways and catwalks during grain drying and storage operations. Our Deck Span® grating provides reliable protection against dangerous conditions, ensuring workers remain safe even when dealing with icy, wet, or slippery walkways. And for grain bin storage, Metalex’s Tread-Grip® flooring provides reliable moisture resistance as the metal allows continuous airflow through the grain — preventing bacterial growth by carrying away moisture. This is especially effective for bin-batch drying methods, which require fully perforated floors for optimal drying.

—Bulk material handling — For these applications, our Open Grip® safety grating provides a strong, corrosion-resistant surface that allows debris to pass through cold-formed holes, keeping walkways clear. This product is also ideal for creating slip-resistant stair treads.

—Heavy trucking — Steps, safety platforms, docks, and loading/unloading areas are all vulnerable to the dangers associated with dirt, ice, rain, heavy loads, and extreme temperatures, in turn posing serious risks for workers. Metalex’s Deck Span® grating and Tread Grip® flooring provide protection against slips and falls and allow for reliable load carrying.

Deck Span® Safety Grating Options

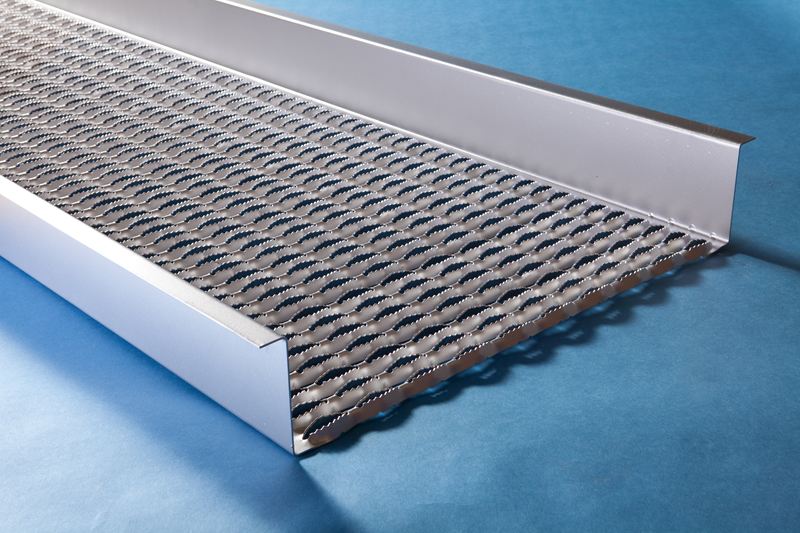

Our Deck Span® safety grating is particularly well-suited to grain drying and storage applications, and is designed with a unique one-piece construction that offers lightweight performance, easy self-framing, and excellent load-carrying capabilities. Below are the various options available for our Deck Span® safety grating.

Our Deck Span® safety grating is particularly well-suited to grain drying and storage applications, and is designed with a unique one-piece construction that offers lightweight performance, easy self-framing, and excellent load-carrying capabilities. Below are the various options available for our Deck Span® safety grating.Deck Span® Safety Grating Standard Channels

—Pre-galvanized or HRP&O steel

—14- and 12-gauge steel

—0.080-inch and 0.100-inch 5052-H32 aluminum

—16-gauge stainless steel 304-2B

—10-foot or 12-foot lengths

Deck Span® Safety Grating Walkways

Deck Span® Safety Grating Stair Treads

—Stock sizes: 24-inch, 30-inch, 36-inch, and 48-inch lengths

—Pre-galvanized or HRP&O steel

—14- and 12-gauge steel

—0.100-inch 5052-H32 aluminum

Learn More

To learn more about our perforated and expanded metal solutions for grain dryers, check out our infographic. And to explore how safety grating can benefit your specific application, download our free eBook, “The Benefits of Safety Grating Over Similar Options.”

Safety Grating for Communication Towers : Safety Every Step of the Way

Comments Off on Safety Grating for Communication Towers : Safety Every Step of the WayFor many industrial companies, work platforms serve as a convenient, efficient way to maximize space. While many businesses use traditional work platforms such as steel mezzanines when building industrial structures, safety grating can be an ideal alternative, offering better protection and further enhancing safety. At Metalex, our safety grating features expanded metal to help prevent slips and falls in the workplace, reliably protecting employees, equipment, and facilities at large across a wide range of industries.

Safety Grating in the Communications Industry

With the ongoing surge in electronic communications, more and more telecom companies are turning to safety grating for use in the construction of communication towers.

With the ongoing surge in electronic communications, more and more telecom companies are turning to safety grating for use in the construction of communication towers.For example, safety grating might be used on the ice bridges of communication towers to protect cables. A tower’s ice bridge sits where the tower’s cables bend horizontally to go down into the equipment platform. Due to its precarious location and the heavy foot traffic involved, ice bridges can benefit greatly from safety grating — especially when used for stair treads and non-slip ladder rungs and catwalks.

Though safety grating is ideal for all types of industrial towers, it’s especially well-suited to communication towers, since it can hold up the extreme temperatures and harsh environments involved. At Metalex, we offer safety grating constructed from top-quality metals that can withstand extreme cold and other outdoor conditions; aluminum, stainless steel, and cold-rolled and hot-rolled steel are popular options. (While hot-rolled steel and cold-rolled steel often need additional pulse treatments or pulse galvanization, aluminum does not.) These metals’ resistance to extreme temperatures makes safety grating ideal for stair treads, in particular.

Lightweight and allowing for easy installation, safety grating is also well-suited to non-slip ladder rungs and catwalks between towers. Featuring enhanced safety features, safety grating reduces the risk of slips and falls, ensuring workers’ safety once they’re in the air moving between towers. In fact, builders can often incorporate safety grating from the ground up in their tower construction. And, allowing for great versatility, safety grating be installed as non-slip stair tread and extend all the way up to the tower’s equipment platform, providing workers with a safe space to work while elevated.

Though individual communication towers do not require a great deal of safety grating, there’s a lot of opportunity in the market as communication towers continue to grow in number.

Types of Communication Towers

Currently, the industry classifies communication towers based on three criteria: 1) structural action, or how the tower is built, 2) the cross section or shape of the tower’s beams (e.g., hexagonal, square, triangular, or polygonal), and 3) the tower’s materials, particularly those used for the tower’s angular or tubular bracings, as well as the surface the tower stands on. In addition, there are four main types of communication towers — monopoles, self-supporting structures, stealth towers, and lattice towers — each offering unique structural characteristics and benefits.

Monopoles are 100–200 feet in height and feature a single-pole design. These towers generally provide cellular and personal communications services. As freestanding structures, they are often built as cylinders or with multiple sides, and they are sometimes even placed on rooftops. Their construction is unique in that the largest diameter is at the bottom, with the rungs consecutively decreasing in size as they go up.

Self-supporting towers are really large guide towers anywhere from 200 to 2,000 feet in height. These towers keep communication cables separate from the structure, so the tower can withstand high winds and extremely high elevations. The strongest of all towers, they are also the most expensive to build due to their large size and material needs. Self-supporting towers are most often used for television, radio, paging services, and cellular services.

Stealth towers have their components stored within a building, so the tower itself is not visible. For example, from the outside, you may just see a large clock, but inside the clock is an unseen antenna collecting data.

Lattice towers are also standalone, freestanding structures. These towers feature a tapered triangle shape, starting at the base and narrowing toward the top. Safety grating is ideal for lattice towers, as they have an identifiable work surface and workers are able to climb up either the inside or outside of the tower. In addition, lattice towers contain individual sections that each contain a maintenance area. On the bottom of these maintenance areas, Metalex’s expanded metal, or mesh, can be extremely useful in providing workers a secure, safe place to stand on while performing their duties.

Metalex offers a wide selection of products to fit any tower’s specific needs. We focus on providing optimal product versatility, and are proud to offer an extensive selection of pattern variations and designs, as well as a range of ferrous and non-ferrous material options. Click the links below to learn more about our safety grating offerings.

Star Deck

Learn More

Our skilled team has more than five decades of collective experience working with expanded metal grating, and can lend their expertise to help you determine which expended metal product best suits your project’s particular needs. To learn more, download our free eBook, “The Benefits of Safety Grating,” or contact us today to speak with one of our product experts.

A wide range of industries and applications make use of safety grating to enhance personnel safety and ensure smooth, efficient operations. In the agricultural sector, for instance, grain drying and storage operations make frequent use of safety grating, as workers must be adequately protected on any walkways exposed to the elements. In these scenarios, grating must be able to perform even in wet or icy conditions. In addition to protecting worker safety, use of proper metal grating can help ensure optimal drying — keeping grain safe from moisture while reducing the risk of extra expenditures and downtime.

A wide range of industries and applications make use of safety grating to enhance personnel safety and ensure smooth, efficient operations. In the agricultural sector, for instance, grain drying and storage operations make frequent use of safety grating, as workers must be adequately protected on any walkways exposed to the elements. In these scenarios, grating must be able to perform even in wet or icy conditions. In addition to protecting worker safety, use of proper metal grating can help ensure optimal drying — keeping grain safe from moisture while reducing the risk of extra expenditures and downtime.

Our Deck Span® safety grating is particularly well-suited to grain drying and storage applications, and is designed with a unique one-piece construction that offers lightweight performance, easy self-framing, and excellent load-carrying capabilities. Below are the various options available for our Deck Span® safety grating.

Our Deck Span® safety grating is particularly well-suited to grain drying and storage applications, and is designed with a unique one-piece construction that offers lightweight performance, easy self-framing, and excellent load-carrying capabilities. Below are the various options available for our Deck Span® safety grating. With the ongoing surge in electronic communications, more and more telecom companies are turning to safety grating for use in the construction of communication towers.

With the ongoing surge in electronic communications, more and more telecom companies are turning to safety grating for use in the construction of communication towers.