Safety Grating in Grain Drying and Storage Applications

A wide range of industries and applications make use of safety grating to enhance personnel safety and ensure smooth, efficient operations. In the agricultural sector, for instance, grain drying and storage operations make frequent use of safety grating, as workers must be adequately protected on any walkways exposed to the elements. In these scenarios, grating must be able to perform even in wet or icy conditions. In addition to protecting worker safety, use of proper metal grating can help ensure optimal drying — keeping grain safe from moisture while reducing the risk of extra expenditures and downtime.

A wide range of industries and applications make use of safety grating to enhance personnel safety and ensure smooth, efficient operations. In the agricultural sector, for instance, grain drying and storage operations make frequent use of safety grating, as workers must be adequately protected on any walkways exposed to the elements. In these scenarios, grating must be able to perform even in wet or icy conditions. In addition to protecting worker safety, use of proper metal grating can help ensure optimal drying — keeping grain safe from moisture while reducing the risk of extra expenditures and downtime.

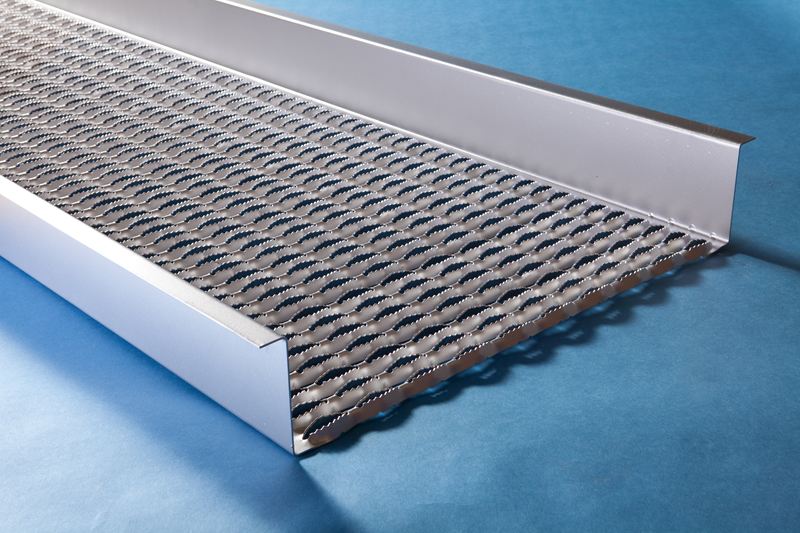

At Metalex, we’re proud to offer our proprietary Deck Span® safety grating, providing peace of mind for workers in potentially dangerous grain drying and storage scenarios. Extremely versatile, this grating can be manufactured for use on catwalks, platforms, balconies, stair treads, and walkways.

Safety Grating in Action

In addition to grain drying, various other operations require safety grating to ensure adequate worker safety, preventing company liability and providing all employees with the confidence they need to get the job done. Below are three areas that can benefit from Metalex’s safety grating products.

—Grain drying and storage — As mentioned earlier, personnel must often traverse exposed walkways and catwalks during grain drying and storage operations. Our Deck Span® grating provides reliable protection against dangerous conditions, ensuring workers remain safe even when dealing with icy, wet, or slippery walkways. And for grain bin storage, Metalex’s Tread-Grip® flooring provides reliable moisture resistance as the metal allows continuous airflow through the grain — preventing bacterial growth by carrying away moisture. This is especially effective for bin-batch drying methods, which require fully perforated floors for optimal drying.

—Bulk material handling — For these applications, our Open Grip® safety grating provides a strong, corrosion-resistant surface that allows debris to pass through cold-formed holes, keeping walkways clear. This product is also ideal for creating slip-resistant stair treads.

—Heavy trucking — Steps, safety platforms, docks, and loading/unloading areas are all vulnerable to the dangers associated with dirt, ice, rain, heavy loads, and extreme temperatures, in turn posing serious risks for workers. Metalex’s Deck Span® grating and Tread Grip® flooring provide protection against slips and falls and allow for reliable load carrying.

Deck Span® Safety Grating Options

Our Deck Span® safety grating is particularly well-suited to grain drying and storage applications, and is designed with a unique one-piece construction that offers lightweight performance, easy self-framing, and excellent load-carrying capabilities. Below are the various options available for our Deck Span® safety grating.

Our Deck Span® safety grating is particularly well-suited to grain drying and storage applications, and is designed with a unique one-piece construction that offers lightweight performance, easy self-framing, and excellent load-carrying capabilities. Below are the various options available for our Deck Span® safety grating.

Deck Span® Safety Grating Standard Channels

—Pre-galvanized or HRP&O steel

—14- and 12-gauge steel

—0.080-inch and 0.100-inch 5052-H32 aluminum

—16-gauge stainless steel 304-2B

—10-foot or 12-foot lengths

Deck Span® Safety Grating Walkways

Deck Span® Safety Grating Stair Treads

—Stock sizes: 24-inch, 30-inch, 36-inch, and 48-inch lengths

—Pre-galvanized or HRP&O steel

—14- and 12-gauge steel

—0.100-inch 5052-H32 aluminum

Learn More

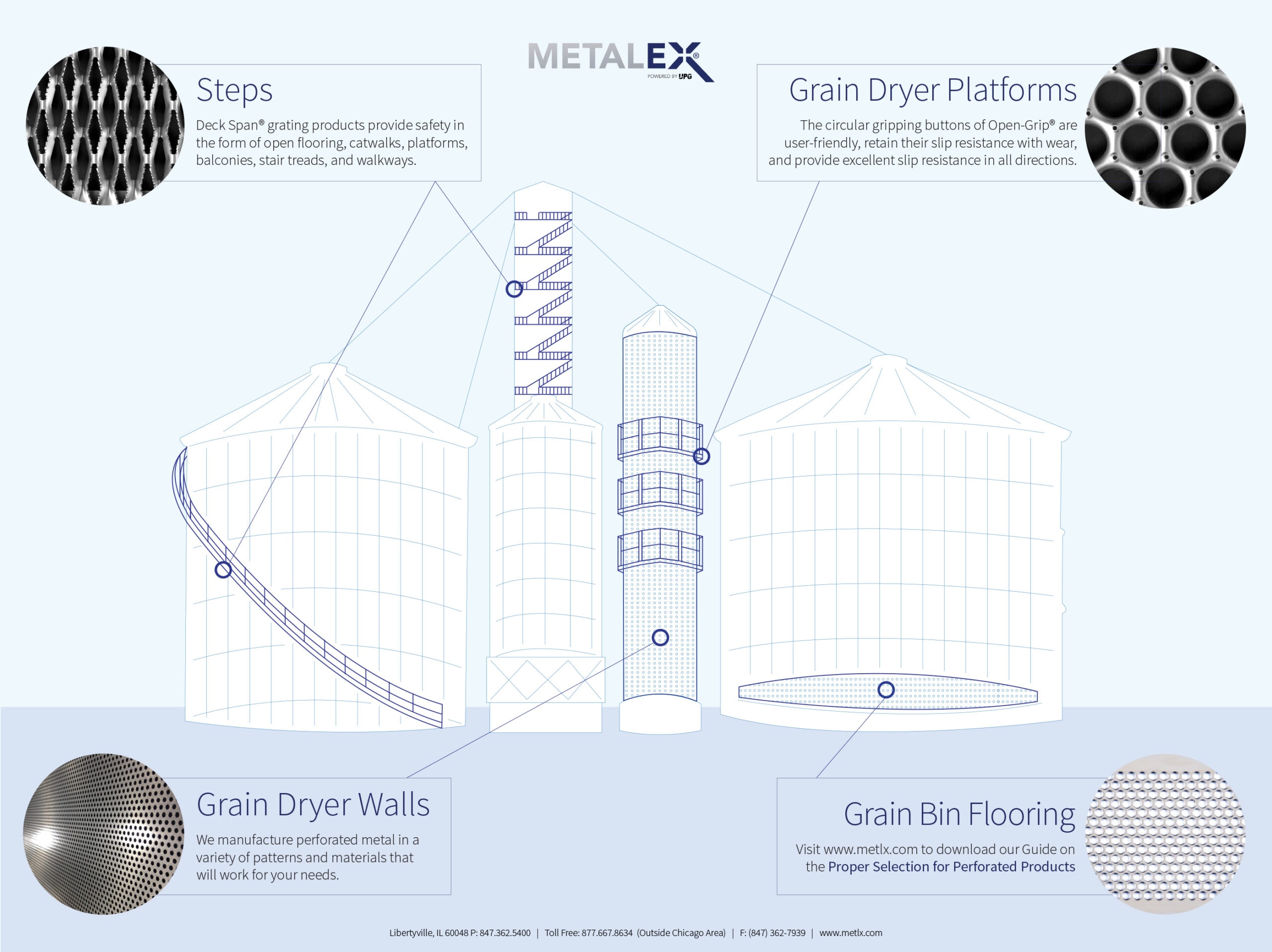

To learn more about our perforated and expanded metal solutions for grain dryers, check out our infographic. And to explore how safety grating can benefit your specific application, download our free eBook, “The Benefits of Safety Grating Over Similar Options.”

Comments are closed