Safety Grating: A Safer Alternative for Work Platforms

Comments Off on Safety Grating: A Safer Alternative for Work PlatformsGaining additional workspace can be difficult in many commercial locations. Platform grating allows for the optimization of vertical space in numerous work environment types, creating a separate and safe working space off the ground. The available variations in work platform design and material ensure options for almost every work environment where vertical space is available.

Importance of Platform Grating

With industrial real estate at very high capacities for the foreseeable future, it’s essential that businesses find ways to optimize their existing workspace. Elevated work platforms help a variety of commercial and industrial businesses to optimize available facility space by leveraging vertical areas that would otherwise go unused. Adding a platform grating loft area to a facility where space is at a premium increases available working areas without the need for expensive internal construction or expansion to the facility.

Platform grating can be customized to meet an expansive range of design and functionality requirements. At Morton Global®, we can tailor our lightweight elevated platforms to meet virtually any need. Our options include:

- All heights and clearances

- Handrails

- Locking mechanisms

- A variety of finishing options

- Perforated or expanded metal treads

- Multiple assembly methods

Our space-saving platform grating can be manufactured from numerous materials, depending on the intended application environment. Options include:

- Aluminum

- Steel

- Stainless steel

Depending on the requirements of your application, the best grating material may differ. We have experts that can advise you on the best material choice.

Platform Grating Applications

Platform grating can be used for a myriad of applications across various commercial and industrial facilities. Some of the common uses for elevated platform grating include:

- Catwalk platforms. Catwalk platforms provide workers in arenas and factories with the opportunity to move safely around the facility.

- Maintenance platforms. Mobile or stationary maintenance platforms provide a secure area to stand when conducting repairs and maintenance on hard-to-reach equipment, offering a safer alternative to ladders.

- Tower platforms. Outdoor platform grating is often used to provide access to communications towers, water towers, elevated storage tanks, and other elevated equipment.

- Office space platforms. Elevated platform grating can provide additional office space without occupying critical floor space in warehouses, distribution centers, machine shops, and more.

- Production/assembly platforms. Platform grating can offer additional production or assembly space for smaller shops with vertical space to spare.

- Storage platforms. Industrial work platforms can provide elevated storage space while still allowing forklifts and foot traffic to pass safely underneath.

- Vehicle platforms. Platform grating provides easier access to elevated heavy equipment, heavy trucks, and trailers. Star Deck from Metalex is ideal for outdoor vehicle and equipment access because it accommodates pass-through for materials and weather.

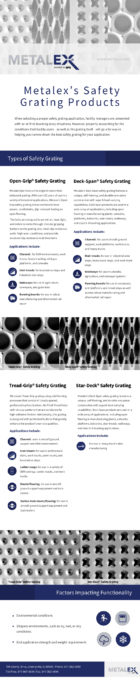

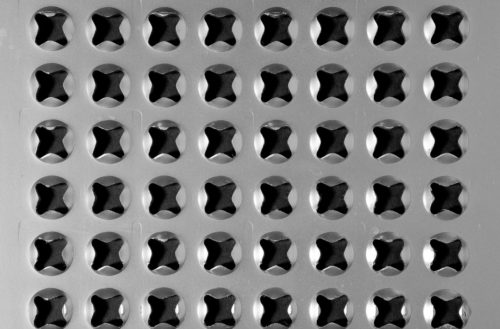

Open-Grip® Safety Grating

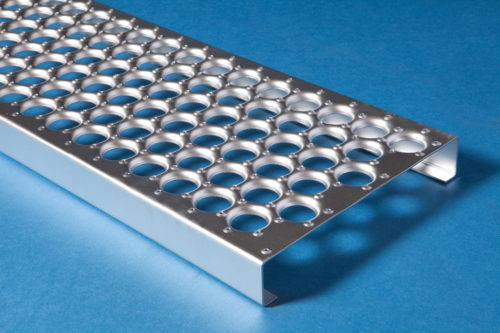

Our Open-Grip® Safety Grating features original round-hole debossed grating. This particular grating is used in a wide a range of industrial applications, in any area requiring safe, comfortable, and slip-resistant footing on open flooring.

Our Open-Grip® Safety Grating features original round-hole debossed grating. This particular grating is used in a wide a range of industrial applications, in any area requiring safe, comfortable, and slip-resistant footing on open flooring.Our Open-Grip® Safety Grating standard channel is available in the following sizes and materials:

—Pre-galvanized or HRP&O steel

—13- and 11-gauge steel

—.125-inch 5052-H32 aluminum

—10-foot or 12-foot lengths – standard sizes

–Custom lengths available upon request

– 5″, 7″, 10″, 12″ +18″ widthsIn addition to standard channels, the Open-Grip® Safety Grating is also available in 24″, 30″ + 36″ walkways.

At Morton Global, we have the ability to “program” the grating pattern, as well as provide end margins, wiped ends, and leading edge holes, giving us unlimited design flexibility in customizing your safety grating.

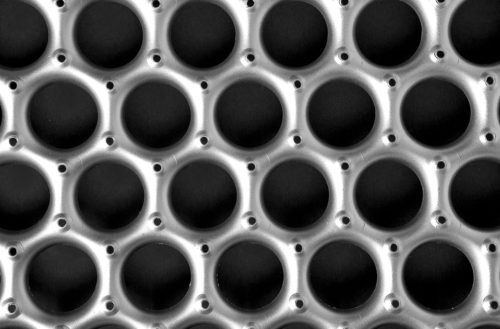

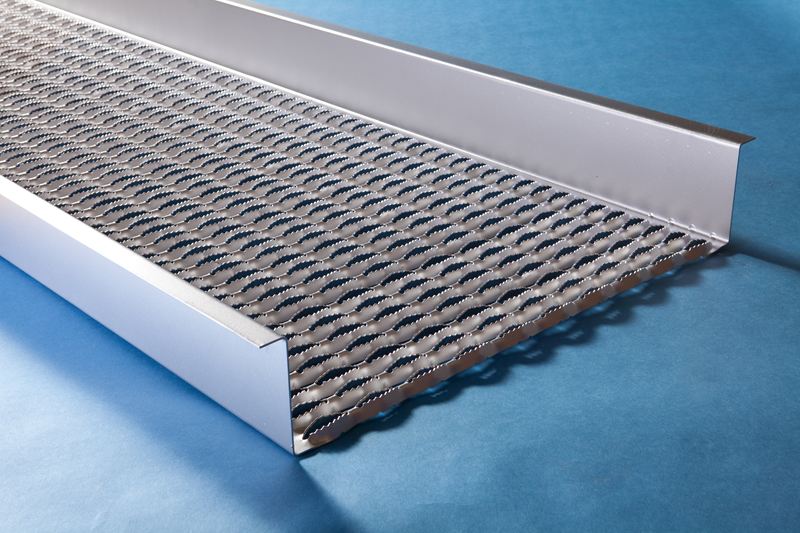

Deck Span® Safety Grating

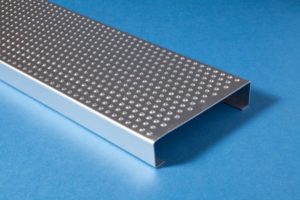

Our Deck Span® Safety Grating, meanwhile, features a unique, one-piece construction that is self-framing and lightweight. Offering high load-bearing capacity, Deck Span® is safe for various plant applications, including open flooring, catwalks, platforms, balconies, stair treads, and walkways. We offer Deck Span® Safety Grating in standard channels, walkways, and stair treads.

Our Deck Span® Safety Grating standard channels are available in the following sizes and materials:

—Pre-galvanized or HRP&O steel

—14- and 12-gauge steel

—.080-inch and .100-inch 5052-H32 aluminum

—16-gauge stainless steel 304-2B

—10-foot or 12-foot standard size lengths

–Custom sizes available upon request

–Available in 2 Diamond (4 3/4″) to 5 Diamond (11 3/4″) wideOur Deck Span® Safety Grating stair treads are available in stock lengths of 24 inches, 30 inches, 36 inches, and 48 inches. They’re offered in pre-galvanized or 14- and 12-gauge HRP&O steel as well as .100-inch 5052-H32 aluminum.

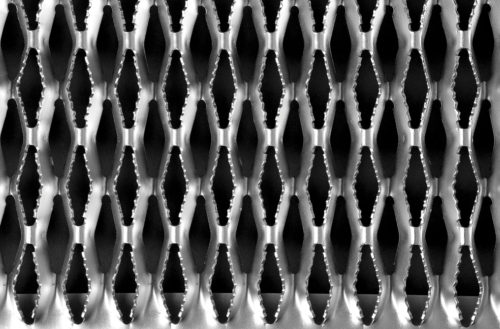

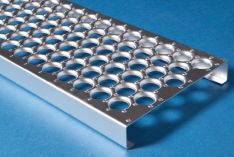

Tread Grip® Flooring

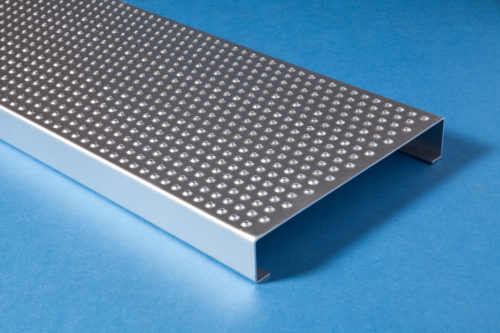

Our Tread Grip® Flooring features closely spaced perforated buttons, produced by cold forming. These buttons are unique in that they create a circular tread pattern, allowing for high-adhesive friction. Thanks to its production process and design, Tread Grip® Flooring can retain its slip resistance for much longer periods of time than other grating options — which, in turn, allows for significant cost savings. While other types of treads depend on outside corners to create friction, Tread Grip®’s high-adhesive friction allows for a long life span. In fact, this type of flooring is frequently used over existing flooring for many different indoor applications. We offer Tread Grip® in standard channels, stair treads, sheets, and ladder rungs.

Our Tread Grip® Safety Grating standard channels are available in the following standard sizes, with the following features and options:

—Pre-galvanized or HRP&O steel

—13- and 11-gauge steel

—.125-inch 5052-H32 aluminum

—10-foot or 12-foot standard lengths

—Margins on all sides

—Integral end caps with mounting holes and slots

—Custom sizes available

—Low open area, preventing debris and tools from falling through

—Custom sizes upon request

—Button-Hole® patterns

–Custom sizes available upon requestOur Tread Grip® Sheets, meanwhile, are available in the following materials and sizes, with the following options:

—11-, 12-, 13-, 14- and 16-gauge HRP&O steel

—125-inch 5052-H32 aluminum

—36 inches wide x 120 inches long

—Other finishes and sizes available by special order

—304-2B stainless steel in 16 gauge (chevron or 1¼-inch square patterns only)

—Safe-Deck™, Chevron, and 1¼-inch square patternsFinally, our Tread Grip® Ladder Rungs come in following materials and sizes, with the following options and features:

—Stock sizes: 16-inch, 18-inch, 48 ¾-inch, and 60-inch lengths

—13- and 11-gauge pre-galvanized or HRP&O steel

—125-inch aluminum

—304-2B stainless steel in 16 gauge

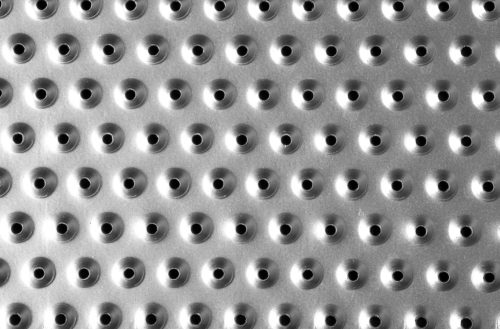

—Safe allowable design loads concentrated at center of span on simple beamStar Deck® Safety Grating

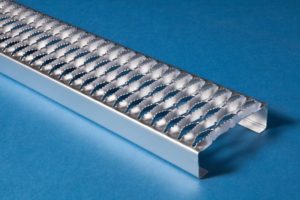

Our Star Deck Safety Grating is low-profile metal grating with high slip-resistant surface. A preferred solution for steps and platforms on heavy equipment, vehicles, and outdoor platforms, this grating’s enhanced slip protection comes from the star-shaped holes. The shape of these cold-embossed holes delivers full 360-degree slip resistance. We can process our Star Deck Safety Grating in sizes up to 11 gauge.

Our Star Deck Safety Grating is available in the following standard sizes and materials:

- HRP&O steel

- 11-gauge steel

- 48” x 100”

Space Saving Solutions From Morton Global

Platform grating is an ideal solution for creating, saving, and optimizing space in a variety of industries and applications. At Morton Global, we offer platform grating in a variety of materials and styles to serve as safe work platforms, catwalks, steps, and much more.

If you are looking to increase the space available in your facility without expensive renovations, please contact us or request a quote today to see how we can help. To learn more about which safety grating will work best for your facility, download our free comprehensive eBook, “The Benefits of Safety Grating.”

Bar Grating vs. Safety Grating: What’s the Difference?

Comments Off on Bar Grating vs. Safety Grating: What’s the Difference?Workplace safety should be a top priority for any employer, but it’s most critical in industrial facilities where the risk of on-the-job injuries is at its peak. Slips, trips and falls are the #1 OSHA recordable instance. Slip and fall accidents cause about 15% of accidental workplace deaths, which highlights the importance of prioritizing safety in every element of a facility’s design, including seemingly harmless components like flooring.

Along with maintaining clean, dry passageways, selecting the appropriate type of grating for your industrial environment is a simple step that can mitigate the risk of such accidents. Safety grating addresses many of the design challenges of traditional bar grating to provide maximum protection to your workforce.

Standard Bar Grating

Standard Bar GratingMetal bar grating has been a mainstay of industrial flooring for decades, consisting of welded steel arranged into a rectangular grid. This type of walkway is strong, versatile, and easy to maintain, making it a popular first choice for many in the industrial design arena.

Common Applications

Bar grating is a popular choice for a variety of applications. It is commonly used in:

- Bridge Flooring

- Trench Covers

- Walkways

- Ramps

- Platforms

- Catwalks

- Mezzanines

Safety Grating: An Innovative Alternative

Safety Grating: An Innovative AlternativeSafety grating offers many of the benefits of bar grating without any of the hazards. It is lighter and cheaper while offering superior slip resistance for moist environments. Metalex offers diamond and round-patterned solutions like Deck Span® and Open Grip®, both of which provide full 360° slip resistance with a safer grid layout than standard bar grating. The narrower holes allow the passage of light while minimizing the risk of larger objects falling through the grate.

Types of Safety Grating

Morton’s safety grating is fully customizable thanks to our programmable die technology and wide inventory of materials. Whatever your application, we can design an optimal safe-passage solution. Our offerings include:

- Open Grip® Safety Grating

- Deck Span® Safety Grating

- Tread Grip® Flooring

- Star Deck® Safety Grating

Applications

Safety grating can be used anywhere bar grating would be installed, including all manner of catwalks, ramps, and walkways. It’s especially recommended for:

- Stair treads

- Vehicle steps

- Work platforms

- Rooftop walkways

- Transportation service areas

- Trailer ladders and platforms

- Truck cap steps

- Tower platforms

- Equipment steps and platforms

Industries

Our safety grating solutions have provided safety benefits to a broad range of applications and industries, including:

- Manufacturing

- Architectural

- Construction

- Agriculture

- Mining

- Cranes and ground support

- Trucking

- Defense and Mass Transit

- Material Handling

- Food Processing

Safety Grating

Bar Grating

Lightweight

✓

Customizable patterns

✓

No-slip surface

✓

✓

Easy to roll pallets/carts

✓

Welded steel composition

✓

Corrosion resistance

✓

Key Considerations

Selecting the optimum flooring is not just a matter of picking between bar grating and safety grating. There are a number of important factors that may affect the outcome of your safety grating installation.

Environment

Morton manufactures safety grating from a wide range of materials to accommodate the needs of diverse industrial settings. To take advantage of this versatility, you’ll want to carefully consider the environment both in and outside of your facility. If you work with corrosive chemicals, for instance, you’ll need to select a material like pre-galvanized steel that offers natural corrosion resistance.

The presence of moisture, ice, oil, or other slippery conditions is another common environmental concern. These risks can be mitigated with the careful application of anti-slip features. Serrated edges or raised buttons may be required to increase traction in such cases.

Weight

Safety grating is a lightweight solution across the board, but some applications may require different strength-to-weight ratios. It’s essential to ensure that the strength of the material can withstand the intended use, including all types of traffic, the weight of items that may be stored on top of the flooring, and more.

Size and Gauge

The width and gauge of the metal also need to be appropriate to the setting to ensure the structure maintains its full integrity throughout its service life.

Pedestrian and Public Use

Public areas with heavy foot traffic expose grating to much higher levels of wear than what is seen within closed facilities. They may also be used by at-risk populations such as children, the elderly, or other at-risk individuals who are more likely to trip or fall. In these cases, materials should be selected for enhanced durability and grip and should be inspected more frequently for damage.

Safety Standards

It is critical to understand and adhere to all OSHA regulations that apply to your facility, including how they relate to the quality and condition of gratings. These requirements may impact steps, platforms, or walkways, and are standard to many industries. Ensuring that any grating you order is in compliance with OSHA guidelines protects users and keeps you in compliance with the law.

Safety Solutions to Protect Your Employees

Metalex is committed to helping you make the best choice for your grating. Our comprehensive eBook, The Benefits of Safety Grating Over Other Options, will help you weigh all of these factors as they relate to your custom needs. If you have more specific questions, we’d be happy to assist you.

Metalex® at Railway Interchange 2019

Comments Off on Metalex® at Railway Interchange 2019

This September, Minneapolis will be hosting Railway Interchange 2019, North America’s largest railway exhibition and technical conference. It brings together hundreds of exhibitors and thousands of international industry professionals every two years. Railway Interchange’s mission is to bring professionals together for authentic discussions and exhibits about the future direction of the industry. The conference is designed to help people inform, inspire, and promote the marketplace by bringing together companies and organizations from across the industry. Over 700 exhibitors will be at Railway Interchange 2019 from September 22–25. Professionals from all organizations in the rail industry can attend the event.

What to Expect

Railway Interchange 2019 will bring together nearly 9,000 railway experts, representatives from technical associations, and industry thought leaders. Attendees will find:

- Over 700 exhibitors

- Presentations and displays from the Railway Engineering-Maintenance Suppliers Association, the Railway Supply Institute, and the Railway Systems Suppliers, Inc. Each organization will be sponsoring exhibits in distinct categories such as track components, railway cars and mechanics, and information technologies, respectively. These presentations will focus on current industry trends and predictions regarding technology, services, and more.

- Discussions and talks presented by The American Railways Engineering and Maintenance-of-Way Association and the Railway Supply Institute. This will include content from the RSI Education & Technical Training Conference.

These presentations, discussions, and exhibit displays will be available through daily open halls and seminars. Along with participating in discussions and listening to talks, attendees can network with industry leaders, representatives from adjacent industry organizations, and thousands of other railway professionals. You can also sign up for:

- Planned educational activities

- AREMA and RSI’s technical training sessions

Where to Find Us

Railway Interchange 2019 attendees can find Metalex® at the conference at booth #2613. Since merging with Morton Rails Products five years ago, Metalex® has attended the event to explore current trends in the railway industry, collaborate with industry partners, and network with other people in our industry.

Morton Rail Products now operates under the Metalex® company name, and we have continued to provide a full line of their products and offerings, including:

- Open-Grip® Running Boards

- DeckSpan® Walkways and Channels

- Brake Steps

- End Platforms

- Ladder Rungs

- Mounting Accessories

These are designed to provide long-lasting, reliable use. Morton Rail Product’s safety grating offers the following advantages:

- Slip resistance. Like all our products, our safety grating exceeds federal specifications regarding slip resistance. This superior slip resistance extends to all directions for safer usage. The surface is also resilient in the face of impact damage and wear. The grating forms a large open area to reduce crowding and accidents.

- Ease of Installation. This product is designed to be simple to install for both small and large companies. The parts are easy to handle, lightweight, and self-framing. The design also allows for one-piece construction so it isn’t difficult to install the grating.

- Low Maintenance Needs. The safety grating is self-cleaning and requires little maintenance to remain safe or in good repair.

- Compliance with ISO 9001 standards. We use 13 gauge G-90 pre-galvanized prime steel to fabricate our brake steps, end platforms, intermodal platforms, and Open-Grip® Running Boards. Also, the full line of Morton Rail Products is approved by the Association of American Railroads.

Contact Metalex® to Learn More

Our line of Morton Rail Products is safe and reliable for every railway facility. Learn more about our products and talk to our team of experts to decide which offerings are the best for your company’s needs. Fill out our form today to download our Morton Industrial Brochure with more details about our complete line of industrial grating, flooring, and custom products.

Application Breakdown of Metalex’s Safety Grating Products

Comments Off on Application Breakdown of Metalex’s Safety Grating Products When selecting a proper safety grating application, facility managers are presented with an at-first daunting array of options. However, properly accounting for the conditions that facility users—as well as the grating itself—will go a far way in helping you narrow down the best safety grating for your application.

When selecting a proper safety grating application, facility managers are presented with an at-first daunting array of options. However, properly accounting for the conditions that facility users—as well as the grating itself—will go a far way in helping you narrow down the best safety grating for your application.Because so many different applications require the use of safety gratings, it’s important to customize these products to your unique needs. Some uses for safety grating include:

- Rail car steps and platforms

- Industrial staircases

- Heavy truck steps

- Catwalks

- Conveyor systems

- Truck trailers

Factors that Affect Your Safety Grating’s Functionality

Safety grating must be able to withstand the unique environmental conditions that it will face. The amount of corrosion and wear to which the grating will be subjected helps determine the type of material to construct it from. For example, pregalvanized steel can resist a wide variety of corrosive agents, but they don’t work perfectly in all circumstances, which puts other anticorrosion tactics such as paint or hot dip galvanization on the table.

Slippery environments, such as icy, wet, or oily conditions, require their own anti-slip customization options. Morton safety grating usually account for this by incorporating serrated edges or raised buttons depending on the types of people and footwear to be used on the gratings—serrated edges may work well for high-intensity applications such as oil rigs and military equipment, but raised buttons are generally safer if the grating’s users include small children.

Finally, safety gratings must satisfy the weight and strength requirements presented by their end application. Most safety grating is constructed from lightweight material, but this makes it more important that the composite material is strong, rigid, and able to withstand foot traffic and environmental conditions.

Metalex offers a wide variety of safety grating, complete with a full suite of customization options. Clients who mix and match from our selection of safety grating offerings will be able to find an end product that will satisfy their strength, weight, shape, and corrosion requirements.

Open-Grip® Safety Grating Product Types

Metalex Open Grip is the original round-hole debossed grating. With over 115 years of use in a variety of industrial applications, Metalex’s Open Grip safety grating allows workers to have secure, comfortable, slip-resistant footing on open flooring.

We create Open-Grip® products using cold-working processes that create raised, perforated buttons and 1/8” to 3/8” debossed holes that permit the flow of air, heat, light, and debris. The circular gripping buttons of Open Grip are user friendly, retain their slip resistance even under high-wear conditions, and provide excellent slip resistance in all directions.

Applications of our Open-Grip® products include:

- Channel

- Pregalvanized and HRPO steel in 11 and 13 gauge

- 125 aluminum

- Self-cleaning and slip-resistant customization options

- Uses in OEM environments, work trucks, heavy trucking, oil and gas platforms, and catwalks

- Stair treads

- Pregalvanized and HRPO steel in 11 and 13 gauge

- 125 aluminum

- Margins on all sides

- Integral end caps and mounting holes and slots

- Used as locomotive steps and industrial stair steps

- Walkways

- Pregalvanized and HRPO steel in 11 and 13 gauge

- Integral toeboards

- OSHA compliance for toeboards on elevations more than 4’ high

- Uses in agriculture, conveyers, and grain bins

- Running boards

- Many types available, including crossovers, end platforms, brake steps, and locomotive steps

- Uses in new railcar manufacturing and aftermarket rail repair

DeckSpan® Product Types

Metalex’s DeckSpan® safety grating features a unique, self-framing, and durable one-piece construction with superb load-carrying capabilities. DeckSpan® products are used in a wide array of applications, including open flooring in manufacturing plants, catwalks, platforms, balconies, stair treads, walkways, and class 5–8 trucking applications.

Applications of DeckSpan® products include:

- Channels

- Pregalvanized and HRPO available in 12 and 14 gauge

- 080 and 0.100 aluminum

- 16-gauge stainless steel

- 1–5 diamond sizes

- Slip resistant

- Self-framing

- Lightweight

- Uses in aircraft ground support, work platforms, work trucks, and heavy trucks

- Walkways

- 10 diamond

- Pregalvanized and HRPO available in 12 and 14 gauge

- Meets OSHA requirements on toeboards for elevations over 4’ high

- Standard lengths of 121.5” to 144”

- Splice kits available upon request

- Uses in catwalks, agriculture, and conveyer systems

- Stair Treads

- Pregalvanized and HRPO available in 12 and 14 gauge

- 2–5 diamond

- Margins on all sides

- Integral end caps with mounting holes and slots

- Custom and standard sizes available

- Uses in industrial area steps, heavy truck steps, and work truck steps

- Running Boards

- Pregalvanized and HRPO available in 12 and 14 gauge

- Uses in crossovers, end platforms, and break steps as well as new railcar manufacturing and aftermarket rail repair

Tread-Grip® Product Types

We create Tread Grip grating using cold-forming processes that consist of closely spaced, perforated surface buttons. We fit all Tread Grips with circular patterns that are conducive for high-adhesive friction. Additionally, this grating is designed with perforated buttons that greatly enhance the product’s non-slip qualities.

Some of the uses of Tread-Grip® include:

- Ladder Rungs

- Options that include two, three, or four buttons per rung

- Pregalvanized and HRPO steel available in 11 and 13 gauge

- 125 aluminum

- 16-gauge stainless steel

- Safe allowable design loads available in our Morton Catalog

- Uses in a variety of OEM settings, tanker trucks, and work trucks

- Channels

- Pregalvanized and HRPO available in 11 and 13 gauge

- 125 aluminum

- Lower open areas, ensuring less room for tools or other items to fall through

- Uses in aircraft ground support and OEM environments

- Sheets/flooring

- HRPO steel available in 11–16 gauge

- 125 aluminum

- Safe-deck, chevron, and 1–1/4” square patterns available

- Uses in aircraft ground support equipment and truck trailers

- Button-Hole Sheets/Flooring

- HRPO steel available in 11–16 gauge

- 125 aluminum

- 16-guage stainless steel

- Square and jumbo patterns

- Multiple sizes available

- Uses as aircraft ground support equipment and truck trailers

- Stair Treads

- Pregalvanized and HRPO available in 11 and 13 gauge

- 125 aluminum

- Margin on all sides

- Integral end caps, mounting holes and slots

- Custom sizes available

- Uses in architectural stairs, work trucks, semi-trucks, and locomotive steps

Star-Deck® Product Types

Star-Deck® safety grating is fitted with evenly spaced star-shaped holes that offer 360° slip resistance. This highly slip-resistant, low-profile metal is commonly used on heavy equipment platforms and steps. Metalex’s unique process allows for countless pattern possibilities.

Star-Deck® sheets and flooring include the following properties:

- 11-gauge HRPO

- Slip resistance

- Uses in heavy truck trailer manufacturing

Safety Grating from Metalex

At Metalex, we provide a wide variety of slip-resistant safety grating to suit any area with foot traffic. With the proper placement, installation, and usage, safety grating can help businesses cultivate safer workplaces.

If you would like to learn more about how our line of safety grating products will benefit your organization, contact us today. You can also download our eBook, “The Benefits of Safety Grating Over Similar Options,” for further information about our products and the benefits they offer.

Safety Appliances to Enhance Truck Safety

Comments Off on Safety Appliances to Enhance Truck SafetySince 1903, Metalex has provided high-quality metal safety grating for customers in a wide variety of industries––from construction, to agricultural, to mining, and many others in between. One such industry that we serve is the heavy truck manufacturing industry, which relies on custom metal components and safety grating for a number of fixtures––including safety platforms and truck steps. With our extensive selection of safety grating, Metalex offers custom metal solutions that ensure safety, convenience, and comfort for heavy truck operators.

Since truck operators work year-round and in all kinds of weather conditions––like sleet, snow, and rain—it’s critical for trucks to be outfitted with fixtures that are both dependable and safe. Our metal safety grating can be a great solution for protecting workers from slips and falls due to our grating’s lightweight design and structure. As a result, many leaders in the heavy truck industry use our safety grating in areas that have a high risk for falls, like truck steps and safety platforms. In these areas, our safety grating provides superior slip resistance and load-bearing capability to give workers enhanced protection and functionality––particularly in icy, dirty, or wet conditions.

Since truck operators work year-round and in all kinds of weather conditions––like sleet, snow, and rain—it’s critical for trucks to be outfitted with fixtures that are both dependable and safe. Our metal safety grating can be a great solution for protecting workers from slips and falls due to our grating’s lightweight design and structure. As a result, many leaders in the heavy truck industry use our safety grating in areas that have a high risk for falls, like truck steps and safety platforms. In these areas, our safety grating provides superior slip resistance and load-bearing capability to give workers enhanced protection and functionality––particularly in icy, dirty, or wet conditions.In addition to steps and platforms, we manufacture other custom metal solutions for the trucking industry, as well. We have a solution for applications that include:

Grills – We manufacture metal grills with enhanced strength capabilities that offer superior protection against dust, debris, and weather. Metalex’s truck grills are available in both perforated and expanded metals––while our perforated metal grills are more resilient to the elements, our expanded metal grills provide less waste and are more structurally sound for heavy truck grills.

Filtration – We provide metal filtration solutions capable of managing both liquid and air. Our filters are ideal for high-pressure handling and enable the flow of materials, like hydraulic fluids, fuel, and outside air, to easily move through systems. Featuring controlled pore sizes to deliver optimal performance, Metalex filters are available in both perforated and expanded metal. Our perforated metal filters are ideal for liquid filtration in trucks’ hydraulic, fuel, and oil systems, while our expanded metal filters are ideal for air filtration, relying on closely managed pore sizes for high performance. We can construct our expanded metal filters from a wide selection of mesh sizes and patterns.

Exhaust Guards – We build our exhaust guards using specially engineered metal patterns that allow airflow to cool trucks’ interior systems. Made from perforated metal, the pattern design in our exhaust guards prevents trucks from overheating and eliminates associated safety issues.

Work Platforms – In addition to truck steps and safety platforms, we also manufacture portable work platforms for flatbed trucks. These platforms protect truck operators from falls and give workers greater security when loading, unloading, and maneuvering cargo.

In our ongoing commitment to safety and quality, Metalex currently offers several safety grating solutions for customers in the trucking industry––and beyond. Our Open Grip® Safety Grating is the original, round-hole debossed grating that allows for the easy flow of air, heat, and light in the truck industry. It can be used in applications wherever safe, comfortable, slip-resistant footing is needed. Our Deck Span® Safety Grating features a unique diamond design that provides 360° slip resistance. In addition, this grating is self-framing and lightweight, and offers outstanding load-carrying capabilities. Lastly, our Tread Grip® Flooring features a circular tread for high-adhesive friction that’s ideal for numerous indoor applications and offers a long lifespan.

Since 1903, Metalex has provided customers with reliable safety grating products that deliver exceptional quality, value, and performance. We are especially proud to offer a large selection of custom metal accessories and solutions for the trucking industry. To learn more about which factors to consider when choosing the right type of safety grating for your trucking application, download our eBook, Safety Grating for Tucking. And to find out more about our specialized safety grating solutions, visit our Markets Applications page.

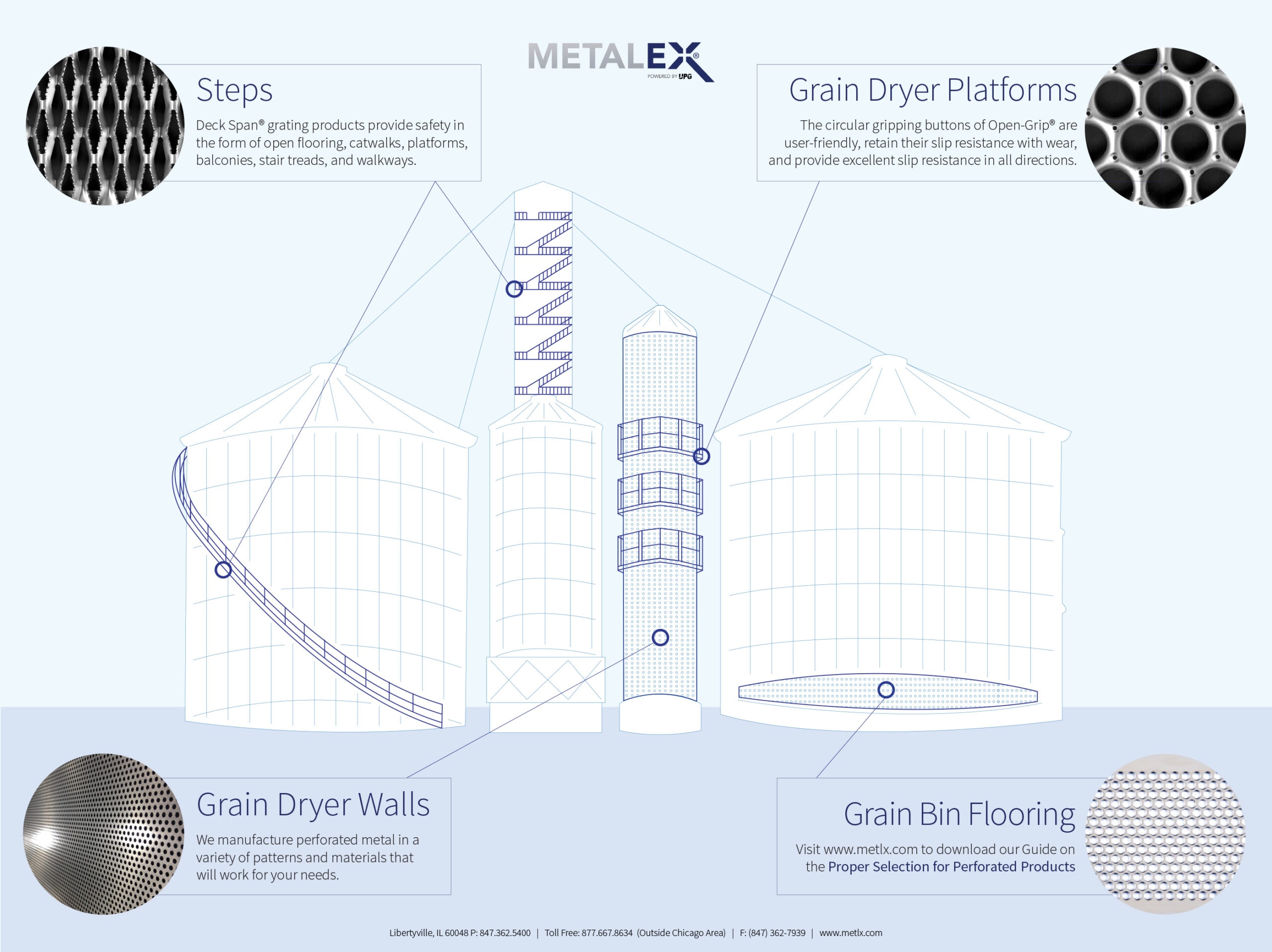

Grain Drying and Storage | Specialty Industries Highlight

Comments Off on Grain Drying and Storage | Specialty Industries HighlightSafety Grating in Grain Drying and Storage Applications

A wide range of industries and applications make use of safety grating to enhance personnel safety and ensure smooth, efficient operations. In the agricultural sector, for instance, grain drying and storage operations make frequent use of safety grating, as workers must be adequately protected on any walkways exposed to the elements. In these scenarios, grating must be able to perform even in wet or icy conditions. In addition to protecting worker safety, use of proper metal grating can help ensure optimal drying — keeping grain safe from moisture while reducing the risk of extra expenditures and downtime.

A wide range of industries and applications make use of safety grating to enhance personnel safety and ensure smooth, efficient operations. In the agricultural sector, for instance, grain drying and storage operations make frequent use of safety grating, as workers must be adequately protected on any walkways exposed to the elements. In these scenarios, grating must be able to perform even in wet or icy conditions. In addition to protecting worker safety, use of proper metal grating can help ensure optimal drying — keeping grain safe from moisture while reducing the risk of extra expenditures and downtime.At Metalex, we’re proud to offer our proprietary Deck Span® safety grating, providing peace of mind for workers in potentially dangerous grain drying and storage scenarios. Extremely versatile, this grating can be manufactured for use on catwalks, platforms, balconies, stair treads, and walkways.

Safety Grating in Action

In addition to grain drying, various other operations require safety grating to ensure adequate worker safety, preventing company liability and providing all employees with the confidence they need to get the job done. Below are three areas that can benefit from Metalex’s safety grating products.

—Grain drying and storage — As mentioned earlier, personnel must often traverse exposed walkways and catwalks during grain drying and storage operations. Our Deck Span® grating provides reliable protection against dangerous conditions, ensuring workers remain safe even when dealing with icy, wet, or slippery walkways. And for grain bin storage, Metalex’s Tread-Grip® flooring provides reliable moisture resistance as the metal allows continuous airflow through the grain — preventing bacterial growth by carrying away moisture. This is especially effective for bin-batch drying methods, which require fully perforated floors for optimal drying.

—Bulk material handling — For these applications, our Open Grip® safety grating provides a strong, corrosion-resistant surface that allows debris to pass through cold-formed holes, keeping walkways clear. This product is also ideal for creating slip-resistant stair treads.

—Heavy trucking — Steps, safety platforms, docks, and loading/unloading areas are all vulnerable to the dangers associated with dirt, ice, rain, heavy loads, and extreme temperatures, in turn posing serious risks for workers. Metalex’s Deck Span® grating and Tread Grip® flooring provide protection against slips and falls and allow for reliable load carrying.

Deck Span® Safety Grating Options

Our Deck Span® safety grating is particularly well-suited to grain drying and storage applications, and is designed with a unique one-piece construction that offers lightweight performance, easy self-framing, and excellent load-carrying capabilities. Below are the various options available for our Deck Span® safety grating.

Our Deck Span® safety grating is particularly well-suited to grain drying and storage applications, and is designed with a unique one-piece construction that offers lightweight performance, easy self-framing, and excellent load-carrying capabilities. Below are the various options available for our Deck Span® safety grating.Deck Span® Safety Grating Standard Channels

—Pre-galvanized or HRP&O steel

—14- and 12-gauge steel

—0.080-inch and 0.100-inch 5052-H32 aluminum

—16-gauge stainless steel 304-2B

—10-foot or 12-foot lengths

Deck Span® Safety Grating Walkways

Deck Span® Safety Grating Stair Treads

—Stock sizes: 24-inch, 30-inch, 36-inch, and 48-inch lengths

—Pre-galvanized or HRP&O steel

—14- and 12-gauge steel

—0.100-inch 5052-H32 aluminum

Learn More

To learn more about our perforated and expanded metal solutions for grain dryers, check out our infographic. And to explore how safety grating can benefit your specific application, download our free eBook, “The Benefits of Safety Grating Over Similar Options.”

Safety Grating for Communication Towers : Safety Every Step of the Way

Comments Off on Safety Grating for Communication Towers : Safety Every Step of the WayFor many industrial companies, work platforms serve as a convenient, efficient way to maximize space. While many businesses use traditional work platforms such as steel mezzanines when building industrial structures, safety grating can be an ideal alternative, offering better protection and further enhancing safety. At Metalex, our safety grating features expanded metal to help prevent slips and falls in the workplace, reliably protecting employees, equipment, and facilities at large across a wide range of industries.

Safety Grating in the Communications Industry

With the ongoing surge in electronic communications, more and more telecom companies are turning to safety grating for use in the construction of communication towers.

With the ongoing surge in electronic communications, more and more telecom companies are turning to safety grating for use in the construction of communication towers.For example, safety grating might be used on the ice bridges of communication towers to protect cables. A tower’s ice bridge sits where the tower’s cables bend horizontally to go down into the equipment platform. Due to its precarious location and the heavy foot traffic involved, ice bridges can benefit greatly from safety grating — especially when used for stair treads and non-slip ladder rungs and catwalks.

Though safety grating is ideal for all types of industrial towers, it’s especially well-suited to communication towers, since it can hold up the extreme temperatures and harsh environments involved. At Metalex, we offer safety grating constructed from top-quality metals that can withstand extreme cold and other outdoor conditions; aluminum, stainless steel, and cold-rolled and hot-rolled steel are popular options. (While hot-rolled steel and cold-rolled steel often need additional pulse treatments or pulse galvanization, aluminum does not.) These metals’ resistance to extreme temperatures makes safety grating ideal for stair treads, in particular.

Lightweight and allowing for easy installation, safety grating is also well-suited to non-slip ladder rungs and catwalks between towers. Featuring enhanced safety features, safety grating reduces the risk of slips and falls, ensuring workers’ safety once they’re in the air moving between towers. In fact, builders can often incorporate safety grating from the ground up in their tower construction. And, allowing for great versatility, safety grating be installed as non-slip stair tread and extend all the way up to the tower’s equipment platform, providing workers with a safe space to work while elevated.

Though individual communication towers do not require a great deal of safety grating, there’s a lot of opportunity in the market as communication towers continue to grow in number.

Types of Communication Towers

Currently, the industry classifies communication towers based on three criteria: 1) structural action, or how the tower is built, 2) the cross section or shape of the tower’s beams (e.g., hexagonal, square, triangular, or polygonal), and 3) the tower’s materials, particularly those used for the tower’s angular or tubular bracings, as well as the surface the tower stands on. In addition, there are four main types of communication towers — monopoles, self-supporting structures, stealth towers, and lattice towers — each offering unique structural characteristics and benefits.

Monopoles are 100–200 feet in height and feature a single-pole design. These towers generally provide cellular and personal communications services. As freestanding structures, they are often built as cylinders or with multiple sides, and they are sometimes even placed on rooftops. Their construction is unique in that the largest diameter is at the bottom, with the rungs consecutively decreasing in size as they go up.

Self-supporting towers are really large guide towers anywhere from 200 to 2,000 feet in height. These towers keep communication cables separate from the structure, so the tower can withstand high winds and extremely high elevations. The strongest of all towers, they are also the most expensive to build due to their large size and material needs. Self-supporting towers are most often used for television, radio, paging services, and cellular services.

Stealth towers have their components stored within a building, so the tower itself is not visible. For example, from the outside, you may just see a large clock, but inside the clock is an unseen antenna collecting data.

Lattice towers are also standalone, freestanding structures. These towers feature a tapered triangle shape, starting at the base and narrowing toward the top. Safety grating is ideal for lattice towers, as they have an identifiable work surface and workers are able to climb up either the inside or outside of the tower. In addition, lattice towers contain individual sections that each contain a maintenance area. On the bottom of these maintenance areas, Metalex’s expanded metal, or mesh, can be extremely useful in providing workers a secure, safe place to stand on while performing their duties.

Metalex offers a wide selection of products to fit any tower’s specific needs. We focus on providing optimal product versatility, and are proud to offer an extensive selection of pattern variations and designs, as well as a range of ferrous and non-ferrous material options. Click the links below to learn more about our safety grating offerings.

Star Deck

Learn More

Our skilled team has more than five decades of collective experience working with expanded metal grating, and can lend their expertise to help you determine which expended metal product best suits your project’s particular needs. To learn more, download our free eBook, “The Benefits of Safety Grating,” or contact us today to speak with one of our product experts.

Specialty Industries Highlight: Material Handling

Comments Off on Specialty Industries Highlight: Material HandlingPlatforms, Walkways, and More

As countless facilities’ managers can attest, slips, trips, and falls top the list of culprits for workplace injuries. Since 1962, the team at Metalex has worked to refine our specialty metal products to offer increased safety — and fewer slips — for every shape, size, and style of work.

Safety Grating in Action

The speed, efficiency, and overall effectiveness of a bulk handling infrastructure rely on optimized layouts and design solutions that incorporate thoughtful, high performance elements throughout the system. Integrating safety grating in walkways, platforms, and potentially hazardous areas is a concrete way to both protect workers and ensure top functionality and longevity for a material handling — or any heavy industrial — workspace.

The speed, efficiency, and overall effectiveness of a bulk handling infrastructure rely on optimized layouts and design solutions that incorporate thoughtful, high performance elements throughout the system. Integrating safety grating in walkways, platforms, and potentially hazardous areas is a concrete way to both protect workers and ensure top functionality and longevity for a material handling — or any heavy industrial — workspace.Safety grating can be helpful to material handling applications of all kinds, including:

Grain Drying and Storage; where personnel often travel walkways and catwalks that are exposed to the elements. Safety grating and materials like Metalex’s Deck Span can provide peace of mind and safety in wet, icy, and otherwise slippery conditions.

Bulk Material Handling; where harsh materials and debris are a constant threat. Safety grating such as Metalex’s Open-Grip creates strong, corrosion-resistant surfaces while allowing debris to pass through cold-formed holes to keep walkways clear. Aggressive, slip-resistant stair treads are also key in these environments.

Heavy Trucking; where load carrying and exposure go hand-in-hand. Steps, safety platforms, docks, and loading/unloading areas are all faced with heavy loads, dirt, ice, rain, and extreme temperatures on a regular basis. Safety grating with slip resistant treads such as Deck Span or Tread-Grip is critical to provide reliable load-carrying and protection from falls under these conditions.

Types and Styles of Safety Grating for Unique Applications

The Metalex catalog of industrial safety grating solutions is easily customizable for your particular application, with unique materials to suit any need. Some of our most popular products for material handling facilities include:

Open-Grip® Safety Grating, our original round hole debossed grating, is specifically developed to provide safe, comfortable, slip-resistant footing on open flooring. Its broad use allows it to improve safety across a variety of industrial applications.

Open-Grip® Safety Grating, our original round hole debossed grating, is specifically developed to provide safe, comfortable, slip-resistant footing on open flooring. Its broad use allows it to improve safety across a variety of industrial applications.Deck Span® Safety Grating, is designed with a unique one-piece construction that offers lightweight performance and easy self-framing. This material offers outstanding load-carrying alongside in-plant safety, making a great fit for catwalks, platforms, stairs, balconies, and walkways.

Tread-Grip® Flooring, produced through cold forming to achieve a surface of closely-spaced perforated buttons, increases grip over existing flooring and indoor spaces. The distinct surface pattern offers long service life and high-adhesive friction for virtually countless applications.

Star Deck Safety Grating, which features star-shaped holes within the metal grating, is designed for high slip-resistance with a low profile. This material, a safer alternative to bar grating, is ideal for heavy equipment platforms and steps, as well as maintenance platforms, ramps, and much more. Thanks to Metalex’s unique manufacturing process, Star Deck Safety Grating can be produced with nearly countless pattern options.

Custom Metal for Material Handling Safety at Metalex

For over five decades, the Metalex Team has worked to offer a wide range of metal solutions to make work more efficient, more effective, and safer for everyone. Our full catalog includes patterns, products, and material options to suit walkways, stairs, tower platforms, and every possible high-risk surface. We work with architects, fabricators, and manufacturers with a single goal: to keep your walkways secure and your employees safe.

Our inventory is stocked with everything from titanium to plastics to cold rolled steel, ready to get the job done. Learn more about implementing our industrial safety products with our free eBook, “The Benefits of Safety Grating,” or reach out to an expert on our team today.

3 Major Industries Utilizing Safety Grating

Comments Off on 3 Major Industries Utilizing Safety GratingWorker and customer safety is the primary focus of any employer, preventing slips and falls is the core of conducting a safe operation.

Safety grating plays a critical role in many applications across various industries, protecting workers while ensuring optimal product functionality and longevity. Below, we’ll take a look at three industries that rely heavily on safety grating.

Grain Drying and Storage

In grain drying, storage, and handling applications, personnel must be adequately protected on walkways that are exposed to the elements; safety grating must perform in wet or icy condition.

In grain drying, storage, and handling applications, personnel must be adequately protected on walkways that are exposed to the elements; safety grating must perform in wet or icy condition.With excellent slip resistance and load-carrying capabilities, Metalex’s Deck Span® safety grating provides peace of mind in outdoor work environments; Deck Span® can be manufactured for use on catwalks, stair treads, and walkways.

Bulk Material Handling

Bulk material handling applications require strong, corrosion-resistant safety grating that can easily

Bulk material handling applications require strong, corrosion-resistant safety grating that can easily

withstand harsh environments. Walkways in the mining industry need to stay clear of debris, perform in inclement weather as well as withstand the wear and tear of falling material and foot traffic alike.Our Open Grip® safety grating features cold-formed raise buttons and debossed holes, allowing debris to pass through and keep walkways clear. Deck Span® safety grating provides an aggressive slip-resistant surface ideal for stair treads.

Heavy Truck

Heavy truck operators must be able to access their equipment safely regardless of weather conditions. Truck steps and safety platforms must be outfitted to provide slip resistance and load-carrying capability, safety grating reliably protects workers from accidental falls when icy, dirty, or wet.

Heavy truck operators must be able to access their equipment safely regardless of weather conditions. Truck steps and safety platforms must be outfitted to provide slip resistance and load-carrying capability, safety grating reliably protects workers from accidental falls when icy, dirty, or wet.Metalex’s Deck Span®’s unique diamond design provides 360° slip resistance, while the debossed holes on Open-Grip® grating permit easy flow of air, heat, and light. Our Tread Grip® flooring features a circular tread for high-adhesive friction and minimal open area.

Learn More

Metalex is proud to offer industry-leading metal solutions to a wide range of applications and industries. Providing a lightweight, versatile alternative to bar grating, our safety grating products can be used in all types of plants and OEM equipment.

To learn more about Metalex’s safety grating solutions, visit our Market Applications page today.

Safety Measures and Creating a Safer Industrial Workplace

Comments Off on Safety Measures and Creating a Safer Industrial WorkplaceThe term “workplace safety” carries more weight in industrial facilities than in traditional office workplaces.

As OSHA outlines in its Walking-Working Surfaces Standard, workplaces — encompassing all passageways, storerooms, and service rooms — should be “kept clean and orderly and in a sanitary condition.” Floors should be clean and dry, and drainage should be present wherever “wet processes are used.”

A trusted manufacturer since 1903, Metalex provides metal anti-slip and fall-prevention products to ensure optimal plant safety across a wide range of industries. For use on walkways, stairs, tower platforms, and more surfaces with heightened safety risk, our industrial safety solutions will keep your walkways secure and your employees safe.

Some of our most popular products include:

Open-Grip® Safety Grating for Rail and Industrial Applications

Commonly used for rail applications, this anti-slip safety grating features round debossed holes through which debris can fall, keeping walkways clear. The design allows for heat, air, and light flow, while raised buttons increase slip resistance.

Commonly used for rail applications, this anti-slip safety grating features round debossed holes through which debris can fall, keeping walkways clear. The design allows for heat, air, and light flow, while raised buttons increase slip resistance.Special features can also be incorporated, including wiped ends, which allow channels to be butted against one another and bolted in order to limit the uneven area, also known as the “lip,” between channels at a joint. Open-Grip® is available in standard channels and walkways; custom product development is available, along with engineering collaboration to ensure your project specific needs are met to a T .

Deck Span® Safety Grating for Plants, Facility, and Construction

Frequently used for applications that require maximum grip, this one-piece, lightweight grating offers the rigidity to handle heavy loads. The self-cleaning diamond surface pattern — formed by cross-hatching and reticulated metal studs — features a serrated edge to provide optimal 360° slip-resistance.

Frequently used for applications that require maximum grip, this one-piece, lightweight grating offers the rigidity to handle heavy loads. The self-cleaning diamond surface pattern — formed by cross-hatching and reticulated metal studs — features a serrated edge to provide optimal 360° slip-resistance.Because this grating’s slip resistance works in all directions, it is ideal for indoor applications such as open flooring, balconies, and catwalks. Deck Span® is offered in various sizes and shapes.

Tread-Grip® Safety Grating for Existing Floors and Indoor Applications

Applied across many industries Tread-Grip® can be found everywhere from tow truck beds to mezzanines and crossovers in manufacturing plans, this grating features closely spaced perforated buttons. Fitted with a circular pattern that increases slip resistance, Tread-Grip® is ideal for high-adhesive friction.

Applied across many industries Tread-Grip® can be found everywhere from tow truck beds to mezzanines and crossovers in manufacturing plans, this grating features closely spaced perforated buttons. Fitted with a circular pattern that increases slip resistance, Tread-Grip® is ideal for high-adhesive friction.The grating is available in ladder rungs, standard channels, stair tread, and sheets; it can also be customized to meet the needs of your specific industrial workplace.

Learn More

To learn more about Metalex’s industrial safety products and how they can be implemented in your facility, visit our website to download our free eBook, “The Benefits of Safety Grating.”

Our Open-Grip® Safety Grating features original round-hole debossed grating. This particular grating is used in a wide a range of

Our Open-Grip® Safety Grating features original round-hole debossed grating. This particular grating is used in a wide a range of

Standard Bar Grating

Standard Bar Grating Safety Grating: An Innovative Alternative

Safety Grating: An Innovative Alternative

Since truck operators work year-round and in all kinds of weather conditions––like sleet, snow, and rain—it’s critical for trucks to be outfitted with fixtures that are both dependable and safe. Our metal safety grating can be a great solution for protecting workers from slips and falls due to our grating’s lightweight design and structure. As a result, many leaders in the heavy truck industry use our safety grating in areas that have a high risk for falls, like truck steps and safety platforms. In these areas, our safety grating provides superior slip resistance and load-bearing capability to give workers enhanced protection and functionality––particularly in icy, dirty, or wet conditions.

Since truck operators work year-round and in all kinds of weather conditions––like sleet, snow, and rain—it’s critical for trucks to be outfitted with fixtures that are both dependable and safe. Our metal safety grating can be a great solution for protecting workers from slips and falls due to our grating’s lightweight design and structure. As a result, many leaders in the heavy truck industry use our safety grating in areas that have a high risk for falls, like truck steps and safety platforms. In these areas, our safety grating provides superior slip resistance and load-bearing capability to give workers enhanced protection and functionality––particularly in icy, dirty, or wet conditions.

A wide range of industries and applications make use of safety grating to enhance personnel safety and ensure smooth, efficient operations. In the agricultural sector, for instance, grain drying and storage operations make frequent use of safety grating, as workers must be adequately protected on any walkways exposed to the elements. In these scenarios, grating must be able to perform even in wet or icy conditions. In addition to protecting worker safety, use of proper metal grating can help ensure optimal drying — keeping grain safe from moisture while reducing the risk of extra expenditures and downtime.

A wide range of industries and applications make use of safety grating to enhance personnel safety and ensure smooth, efficient operations. In the agricultural sector, for instance, grain drying and storage operations make frequent use of safety grating, as workers must be adequately protected on any walkways exposed to the elements. In these scenarios, grating must be able to perform even in wet or icy conditions. In addition to protecting worker safety, use of proper metal grating can help ensure optimal drying — keeping grain safe from moisture while reducing the risk of extra expenditures and downtime.

Our Deck Span® safety grating is particularly well-suited to grain drying and storage applications, and is designed with a unique one-piece construction that offers lightweight performance, easy self-framing, and excellent load-carrying capabilities. Below are the various options available for our Deck Span® safety grating.

Our Deck Span® safety grating is particularly well-suited to grain drying and storage applications, and is designed with a unique one-piece construction that offers lightweight performance, easy self-framing, and excellent load-carrying capabilities. Below are the various options available for our Deck Span® safety grating. With the ongoing surge in electronic communications, more and more telecom companies are turning to safety grating for use in the construction of communication towers.

With the ongoing surge in electronic communications, more and more telecom companies are turning to safety grating for use in the construction of communication towers. The speed, efficiency, and overall effectiveness of a bulk handling infrastructure rely on optimized layouts and design solutions that incorporate thoughtful, high performance elements throughout the system. Integrating safety grating in walkways, platforms, and potentially hazardous areas is a concrete way to both protect workers and ensure top functionality and longevity for a material handling — or any heavy industrial — workspace.

The speed, efficiency, and overall effectiveness of a bulk handling infrastructure rely on optimized layouts and design solutions that incorporate thoughtful, high performance elements throughout the system. Integrating safety grating in walkways, platforms, and potentially hazardous areas is a concrete way to both protect workers and ensure top functionality and longevity for a material handling — or any heavy industrial — workspace.

In

In  Bulk material handling applications

Bulk material handling applications Heavy truck operators must be able to access their equipment safely regardless of weather conditions. Truck steps and safety platforms must be outfitted to provide slip resistance and load-carrying capability, safety grating reliably protects workers from accidental falls when icy, dirty, or wet.

Heavy truck operators must be able to access their equipment safely regardless of weather conditions. Truck steps and safety platforms must be outfitted to provide slip resistance and load-carrying capability, safety grating reliably protects workers from accidental falls when icy, dirty, or wet.