When selecting a proper safety grating application, facility managers are presented with an at-first daunting array of options. However, properly accounting for the conditions that facility users—as well as the grating itself—will go a far way in helping you narrow down the best safety grating for your application.

When selecting a proper safety grating application, facility managers are presented with an at-first daunting array of options. However, properly accounting for the conditions that facility users—as well as the grating itself—will go a far way in helping you narrow down the best safety grating for your application.

Because so many different applications require the use of safety gratings, it’s important to customize these products to your unique needs. Some uses for safety grating include:

- Rail car steps and platforms

- Industrial staircases

- Heavy truck steps

- Catwalks

- Conveyor systems

- Truck trailers

Factors that Affect Your Safety Grating’s Functionality

Safety grating must be able to withstand the unique environmental conditions that it will face. The amount of corrosion and wear to which the grating will be subjected helps determine the type of material to construct it from. For example, pregalvanized steel can resist a wide variety of corrosive agents, but they don’t work perfectly in all circumstances, which puts other anticorrosion tactics such as paint or hot dip galvanization on the table.

Slippery environments, such as icy, wet, or oily conditions, require their own anti-slip customization options. Morton safety grating usually account for this by incorporating serrated edges or raised buttons depending on the types of people and footwear to be used on the gratings—serrated edges may work well for high-intensity applications such as oil rigs and military equipment, but raised buttons are generally safer if the grating’s users include small children.

Finally, safety gratings must satisfy the weight and strength requirements presented by their end application. Most safety grating is constructed from lightweight material, but this makes it more important that the composite material is strong, rigid, and able to withstand foot traffic and environmental conditions.

Metalex offers a wide variety of safety grating, complete with a full suite of customization options. Clients who mix and match from our selection of safety grating offerings will be able to find an end product that will satisfy their strength, weight, shape, and corrosion requirements.

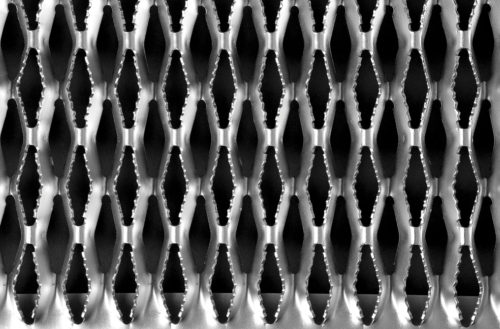

Open-Grip® Safety Grating Product Types

Metalex Open Grip is the original round-hole debossed grating. With over 115 years of use in a variety of industrial applications, Metalex’s Open Grip safety grating allows workers to have secure, comfortable, slip-resistant footing on open flooring.

We create Open-Grip® products using cold-working processes that create raised, perforated buttons and 1/8” to 3/8” debossed holes that permit the flow of air, heat, light, and debris. The circular gripping buttons of Open Grip are user friendly, retain their slip resistance even under high-wear conditions, and provide excellent slip resistance in all directions.

Applications of our Open-Grip® products include:

- Channel

- Pregalvanized and HRPO steel in 11 and 13 gauge

- 125 aluminum

- Self-cleaning and slip-resistant customization options

- Uses in OEM environments, work trucks, heavy trucking, oil and gas platforms, and catwalks

- Stair treads

- Pregalvanized and HRPO steel in 11 and 13 gauge

- 125 aluminum

- Margins on all sides

- Integral end caps and mounting holes and slots

- Used as locomotive steps and industrial stair steps

- Walkways

- Pregalvanized and HRPO steel in 11 and 13 gauge

- Integral toeboards

- OSHA compliance for toeboards on elevations more than 4’ high

- Uses in agriculture, conveyers, and grain bins

- Running boards

- Many types available, including crossovers, end platforms, brake steps, and locomotive steps

- Uses in new railcar manufacturing and aftermarket rail repair

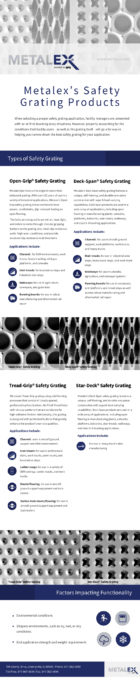

DeckSpan® Product Types

Metalex’s DeckSpan® safety grating features a unique, self-framing, and durable one-piece construction with superb load-carrying capabilities. DeckSpan® products are used in a wide array of applications, including open flooring in manufacturing plants, catwalks, platforms, balconies, stair treads, walkways, and class 5–8 trucking applications.

Applications of DeckSpan® products include:

- Channels

- Pregalvanized and HRPO available in 12 and 14 gauge

- 080 and 0.100 aluminum

- 16-gauge stainless steel

- 1–5 diamond sizes

- Slip resistant

- Self-framing

- Lightweight

- Uses in aircraft ground support, work platforms, work trucks, and heavy trucks

- Walkways

- 10 diamond

- Pregalvanized and HRPO available in 12 and 14 gauge

- Meets OSHA requirements on toeboards for elevations over 4’ high

- Standard lengths of 121.5” to 144”

- Splice kits available upon request

- Uses in catwalks, agriculture, and conveyer systems

- Stair Treads

- Pregalvanized and HRPO available in 12 and 14 gauge

- 2–5 diamond

- Margins on all sides

- Integral end caps with mounting holes and slots

- Custom and standard sizes available

- Uses in industrial area steps, heavy truck steps, and work truck steps

- Running Boards

- Pregalvanized and HRPO available in 12 and 14 gauge

- Uses in crossovers, end platforms, and break steps as well as new railcar manufacturing and aftermarket rail repair

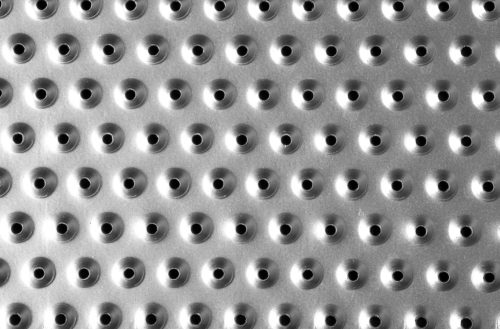

Tread-Grip® Product Types

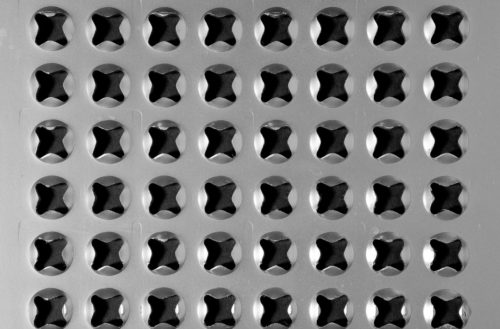

We create Tread Grip grating using cold-forming processes that consist of closely spaced, perforated surface buttons. We fit all Tread Grips with circular patterns that are conducive for high-adhesive friction. Additionally, this grating is designed with perforated buttons that greatly enhance the product’s non-slip qualities.

Some of the uses of Tread-Grip® include:

- Ladder Rungs

- Options that include two, three, or four buttons per rung

- Pregalvanized and HRPO steel available in 11 and 13 gauge

- 125 aluminum

- 16-gauge stainless steel

- Safe allowable design loads available in our Morton Catalog

- Uses in a variety of OEM settings, tanker trucks, and work trucks

- Channels

- Pregalvanized and HRPO available in 11 and 13 gauge

- 125 aluminum

- Lower open areas, ensuring less room for tools or other items to fall through

- Uses in aircraft ground support and OEM environments

- Sheets/flooring

- HRPO steel available in 11–16 gauge

- 125 aluminum

- Safe-deck, chevron, and 1–1/4” square patterns available

- Uses in aircraft ground support equipment and truck trailers

- Button-Hole Sheets/Flooring

- HRPO steel available in 11–16 gauge

- 125 aluminum

- 16-guage stainless steel

- Square and jumbo patterns

- Multiple sizes available

- Uses as aircraft ground support equipment and truck trailers

- Stair Treads

- Pregalvanized and HRPO available in 11 and 13 gauge

- 125 aluminum

- Margin on all sides

- Integral end caps, mounting holes and slots

- Custom sizes available

- Uses in architectural stairs, work trucks, semi-trucks, and locomotive steps

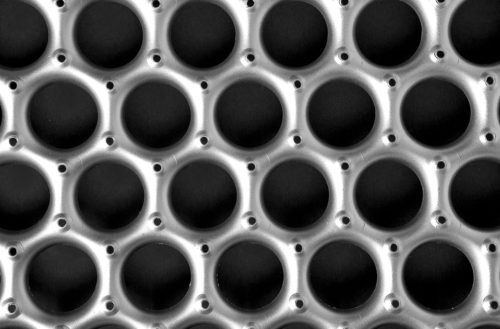

Star-Deck® Product Types

Star-Deck® safety grating is fitted with evenly spaced star-shaped holes that offer 360° slip resistance. This highly slip-resistant, low-profile metal is commonly used on heavy equipment platforms and steps. Metalex’s unique process allows for countless pattern possibilities.

Star-Deck® sheets and flooring include the following properties:

- 11-gauge HRPO

- Slip resistance

- Uses in heavy truck trailer manufacturing

Safety Grating from Metalex

At Metalex, we provide a wide variety of slip-resistant safety grating to suit any area with foot traffic. With the proper placement, installation, and usage, safety grating can help businesses cultivate safer workplaces.

If you would like to learn more about how our line of safety grating products will benefit your organization, contact us today. You can also download our eBook, “The Benefits of Safety Grating Over Similar Options,” for further information about our products and the benefits they offer.

Comments are closed