Types of Railcars Using Morton Rail Products

Comments Off on Types of Railcars Using Morton Rail ProductsThe railroad industry is responsible for moving a wide range of cargo throughout the United States. Railcars come in a variety of styles, each designed to carry specific types of goods ranging from industrial equipment and timber to oil and liquids.

Metalex’s line of Morton Rail Products—including brake steps, end platforms, tank straps, side sheets, and running boards—are used for transporting all different kinds of freight by rail. The Morton Manufacturing Company name has been a staple in the railroad sector for decades. Metalex and Morton merged in 2014 and continue to operate under the Metalex name. We continue to provide reliable safety solutions used in railroad operations, such as non-slip walking surface for rail platforms.

Morton safety grating is ideal for large open areas and exceeds basic federal standards for slip-resistant surfaces. Other advantages include:

- Easy installation and handling

- Single-piece construction

- Lightweight

- Omni-directional slip resistance

- Minimal maintenance requirements

- Self-cleaning

- Self-framing

This blog post will discuss the various types of freight rail cars and the Morton safety products that support them.

Autocarriers

Autocarriers —also known as car transporters—are built to handle large, bulky loads. They are most typically used to secure automobiles or heavy equipment for rail transport.

These heavy-duty railcars rely on Morton’s perforated metal side sheets and logo panels to keep vehicles and other bulky freight safe from damage, vandals, or debris and dirt. The perforated metal construction acts as a shield during rail transport. The perforated metal also allows light and air to pass through, preventing moisture build-up that could lead to corrosion.

Tank Cars

Tank cars carry a broad range of liquids—many of them flammable or potentially dangerous, such as chemicals, ethanol, and oil. Rail has become the go-to alternative for oil transport since the United States and Canada continue to produce higher amounts of oil that can’t be handled by existing pipelines.

To ensure the safety of people and property, Transport Canada and the U.S. Department of Transportation have imposed strict regulations for freight cars carrying oil and other sensitive liquid loads. As such, thousands of existing tank cars are being retrofitted with additional steel jackets and other safety appliances.

In response to these changing demands, Metalex provides a range of products that can be used to upgrade older cars or improve safety on new ones. Products used on tank cars include:

Tank Straps

These straps wrap around the circumference of older tank cars that don’t meet new regulations, creating a gap that can be used for insulation and thermal protection in accordance with new standards.

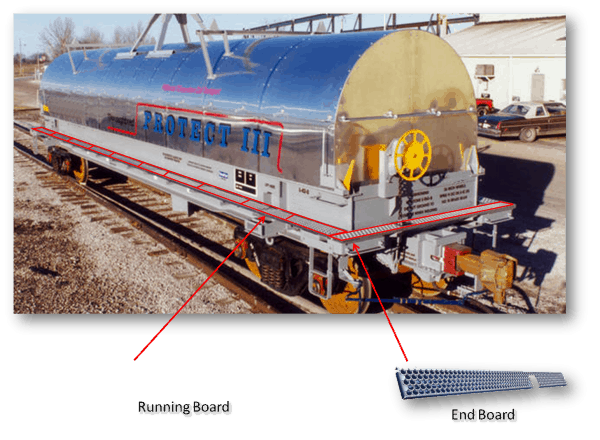

Tread-Grip® and DeckSpan®

Our safety grating solutions provide safe walking surfaces on or above tank cars. The unique diamond design offers 360° slip resistance. Our safety grating is also lighter than traditional bar grating products, improving the load capacity of the tank car.

Ladder Rungs

We offer Tread-Grip® for ladder rungs as well. This non-slip surface enhances the safety and usability of tank car ladders by providing high-adhesive friction and extending equipment service life.

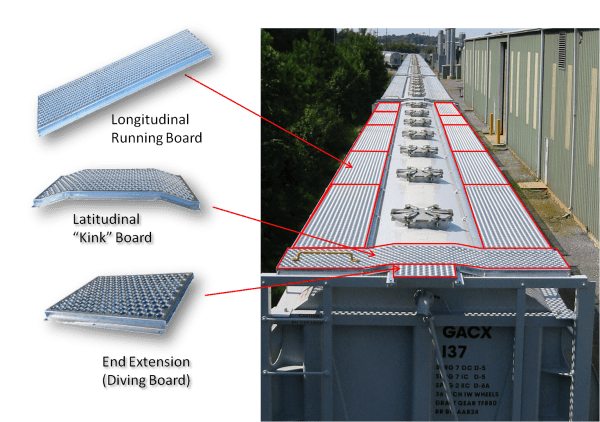

Hopper Cars

Hopper cars transport loose cargo such as coal, ore, grain, and sugar. Hopper cars are typically top loaded. As such, hoppers require crossover boards—sometimes referred to as platform boards or running boards—that enable workers to safely cross the open space across the top of the car. Metalex offers Open Grip® safety grating on our crossover boards to provide improved slip resistance and grip for rail workers. We also offer Open-Grip® end extensions in addition to crossover boards.

Intermodal Well Cars

Simply put, well cars are built specifically to carry shipping containers. Intermodal shipping containers are used by ocean carriers, trucking carriers, and rail carriers around the world to safely and efficiently standardize cargo movement between transport modes without the need to repack the items within the container.

Intermodal well cars may also be referred to as double-stack cars, or simply stack cars, as they can accommodate two shipping containers stacked on top of each other while remaining low enough to meet clearances for standard rail tunnels. As many shipping containers may contain very heavy loads, well cars are typically equipped with six or more axles to handle any shipment weight without need for adjustment.

Metalex’s line of Morton Rail Products includes slip-resistant train platforms and walkways featuring our proprietary Open-Grip® design. Our circular gripping pattern not only provides improved grip, but also features self-drainage so water, dirt, and debris won’t build up on the surface during operation or transport.

Boxcars

Rail boxcars—so named because they are essentially an enclosed box—are perhaps one of the most commonly recognized types of railcar. They may be used to move a very broad variety of freight, ranging from loose agricultural goods, livestock, coal, ore, lumber, boxed goods, canned foods, and much more.

Boxcars are available in a wide variety of styles, which contributes to their operational versatility. Features may include:

- Plug or sliding doors

- Single or double doors

- Cushioned or non-cushioned door underframes

- Insulated or non-insulated interiors

- Internal load-handling mechanisms (linings, straps, tie-downs, nets, etc.)

Metalex’s line of Morton Rail Products offers a range of solutions suitable for use in boxcars, such as:

- Open-Grip steps

- Open-Grip platforms

- Tread-Grip ladder rungs

Rail Components From Metalex

No matter what type of rail car you work with, Metalex provides a full line of reliable products that will improve the quality, longevity, and safety or your rail operation. For more information about our line of Morton Rail Products, please download Metalex’s Morton Industrial brochure.