Metal Solutions for the Architectural Industry

Comments Off on Metal Solutions for the Architectural Industry Metals have many inherent qualities, including strength, malleability, and durability, that make them ideal building components. Recently, architects and contractors have begun adopting new metal solutions to improve building performance, aesthetics, and safety. Two of the most common techniques, perforated and expanded metal, are particularly prized for their high strength, reliability, and flexibility, and their ability to provide high levels of security make them particularly beneficial for new or rehabbed buildings.

Metals have many inherent qualities, including strength, malleability, and durability, that make them ideal building components. Recently, architects and contractors have begun adopting new metal solutions to improve building performance, aesthetics, and safety. Two of the most common techniques, perforated and expanded metal, are particularly prized for their high strength, reliability, and flexibility, and their ability to provide high levels of security make them particularly beneficial for new or rehabbed buildings.Below, we’ve outlined some of the main uses of perforated and expanded metals, as well as some qualitative benefits they’ll bring to your next construction project.

Metal Solutions

Perforated and expanded metals can form a variety of innovative products, composites, and sustainable design solutions that will perform well across a range of climates and building types. Here are some of these metals’ most common applications:

Ceiling Ducts

Perforated metals evenly distribute air in ceiling ducts and reduce excessive noise typical to HVAC systems. Many companies provide a wide selection of architectural perforated metal products to be considered for each construction project.

Security Mesh inside Walls, Ceilings, and Floors

Security Mesh inside Walls, Ceilings, and FloorsBarrier and security fence manufacturers use expanded metals to create meshes for use on walls, ceilings, or floors. Because of their inherent strength, expanded metal barrier meshes can protect against break-ins and break-outs, ensuring the safety of facilities and the people using them.

Stairs, Railings, and Arches

High-performance metals allow for complex, intricate designs in stairs, railings, and arches while meeting safety and durability requirements. By incorporating metal solutions into their plans, architects can design more creative and competitive solutions and incorporate delicacy into their design without sacrificing function.

Siding and Roofing

Because of their malleability, you can easily form perforated and expanded metals into a variety of shapes. Consequently, using these metals for your roofing or siding can be an extremely affordable, versatile, and effective solution, especially in high–wind uplift conditions.

Other Uses

Expanded and perforated metals also work well in architectural fencing, facades, lighting, doors, gates, lockers, office dividers, privacy screens, sunshades, sunscreens, windows, and skylight guards.

Benefits of Metal Solutions in Architecture

Making use of innovative new metal solutions allows for trade collaboration in the architectural industry. The large range of customization capabilities for perforated and expanded metals allows for a great deal of collaboration to take place between suppliers and clients. Because these metals can come in so many shapes, forms, and abilities, they offer limitless possibilities.

Making use of innovative new metal solutions allows for trade collaboration in the architectural industry. The large range of customization capabilities for perforated and expanded metals allows for a great deal of collaboration to take place between suppliers and clients. Because these metals can come in so many shapes, forms, and abilities, they offer limitless possibilities.High-performance materials such as expanded and perforated metals also boost your buildings’ integrity and longevity. Their ability to easily form and conform to new applications enables these metals to provide solutions to previously hard-to-solve problems.

Finally, implementing new metal-forming techniques helps architects meet or exceed building code requirements for complex issues such as water penetration, uplift ratings, fire protection, and seismic and structural performance.

Use Perforated and Expanded Metals in Your Next Construction Project

New metal-forming techniques are taking the market by storm. Adopting perforated and expanded metals for your next architectural project will provide the same degree of security and metal coverage as other techniques, but will consume fewer resources while doing so

Decorative Expanded Metal for Architectural Design

Comments Off on Decorative Expanded Metal for Architectural DesignIn recent years, many suppliers have begun working with architects, contractors, and fabricators to incorporate expanded metal into architectural projects; offering great versatility and many customization options, this metal is well-suited to a huge range of design applications.

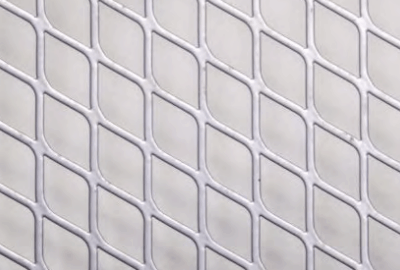

Expanded metal is created during a coil-fed process in which raw material is simultaneously slitted and stretched, creating uniform diamond-shaped openings. The diamond-shaped trusses form a sharp angle to the original plane of the sheet, adding strength and rigidity. Depending on the desired use, expanded metal can be recoiled or blanked into sheets. This versatile material is available in standard, raised, flattened, and decorative diamond patterns, and comes in a range of gauges, opening sizes, finishes, materials, and sheet sizes. Metalex also offers inline flattening and inline slitting services.

Decorative Expanded Metal

An intermediate raw material, expanded metal allows light and air to flow freely through it while still serving as a rigid screen solution with a variety of open-area configuration options. It’s available in carbon steel, aluminum, copper, nickel, and several other alloys. With its flattened and raised profiles, it provides a three-dimensional look that perforated metals cannot. The production process for expanded metal produces zero scrap and requires considerably less raw material than perforated options, making it an ideal choice for sustainable designs.

An intermediate raw material, expanded metal allows light and air to flow freely through it while still serving as a rigid screen solution with a variety of open-area configuration options. It’s available in carbon steel, aluminum, copper, nickel, and several other alloys. With its flattened and raised profiles, it provides a three-dimensional look that perforated metals cannot. The production process for expanded metal produces zero scrap and requires considerably less raw material than perforated options, making it an ideal choice for sustainable designs.Since it’s available in a wide range of patterns and textures it’s well-suited to many architectural design components; architects and designers turn to expanded metal for its decorative value, but also for the reliable support and protection it offers. Highly durable, expanded metal typically retains its shape over time, even after being in use for several years. It also offers great flexibility, strength, and rigidity, and can be used to control light and airflow — as well as overall visibility to allow for privacy in hotels, buildings, offices, and other establishments. Highly versatile, decorative expanded metal can lend a sophisticated, sleek appearance to all kinds of architectural and design projects.

Plus, expanded metal tooling costs are typically one-third of that of their perforated counterparts, making customization much less costly.

Versatile Form and Function

Allowing for a modern, aesthetically pleasing finishing touch, expanded metals are ideal for highly visible interior design and exterior features, offering an unparalleled level of control over appearance and function. Shifts in sunlight and season allow these unique materials to shine, subtly playing off the light. Expanded metals are also ideal for various outdoor uses, including facades, fencing, cladding, fire escapes, gates, sunshades, and walkways. Popular indoor applications include ceiling and wall lighting, ceiling panels, doors, interior design, partitions, lockers, office dividers, privacy screens, stairways, windows, and skylight guards.

Decorative expanded metal can also be used as a pass-through to support sound absorption in ceilings and walls, as well as serve as protective or decorative coverings for special acoustical materials.

Learn More

Contact Metalex today to learn more about our line of expanded metal products or discuss how decorative expanded metal can benefit your next project. We’re on hand to answer any questions you may have.

Uses for Engineered Metal in Architectural Design

Comments Off on Uses for Engineered Metal in Architectural DesignEngineered metal is a key element in many architectural projects.

Metalex engineers work with architects and designers to develop the appropriate pattern and style to meet the demands of almost any project. Our coil-fed processing and breadth of manufacturing capabilities allow us to efficiently produce safety grating, security fencing, sunshades, facades, and ceiling panels for architectural applications.

There are an astounding range of applications for converted sheet metal. From the most utilitarian functional walkway to an artistic accent, the possibilities are endless.

Perforated Metal

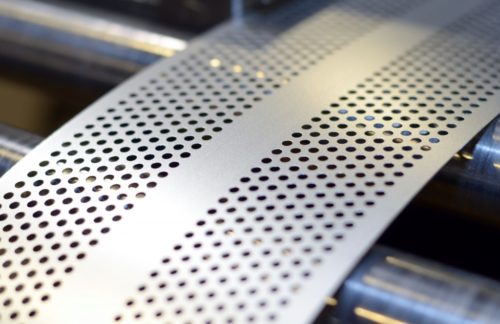

Perforated metal is produced when a raw material is coil-fed into one of our high speed presses. The metal is punched on the downstroke of the press and the material advances on the upstroke of the press. The size, shape, and pattern of perforations are manufactured according to your needs and precise aesthetic purpose.

Perforated metal is produced when a raw material is coil-fed into one of our high speed presses. The metal is punched on the downstroke of the press and the material advances on the upstroke of the press. The size, shape, and pattern of perforations are manufactured according to your needs and precise aesthetic purpose.Strokes can be skipped in order to create gaps or margins perpendicularly across the material, and sections of punches can be gagged to create a parallel center margin or rectangular element of un-punched space within the pattern.

Safety Grating

Safety grating is produced when a raw material is coil-fed into a heavy duty die press.

However, safety grating is produced exclusively in a coil-to-sheet process: a coil feeds the machine and a cut to be made at a set length upon exiting the press. Metalex offers a unique programmable die which allows for sections of the pattern to be gaged and angles or unique shapes to go punctured through the press.

Expanded Metal

Expanded metal is produced through a coil-fed process in which raw material is simultaneously slit and stretched creating uniform diamond-shaped openings. Expanded metal can be recoiled or blanked into sheets depending on the desired end use. Metalex offers inline flattening and inline slitting on our expanded metal production lines.

Learn More

Metalex’s expertise on engineered metal for architecture was recently in Engineering.com. Read the article for more information.

Metals have many inherent qualities, including strength, malleability, and durability, that make them ideal building components. Recently, architects and contractors have begun adopting new metal solutions to improve building performance, aesthetics, and safety. Two of the most common techniques, perforated and expanded metal, are particularly prized for their high strength, reliability, and flexibility, and their ability to provide high levels of security make them particularly beneficial for new or rehabbed buildings.

Metals have many inherent qualities, including strength, malleability, and durability, that make them ideal building components. Recently, architects and contractors have begun adopting new metal solutions to improve building performance, aesthetics, and safety. Two of the most common techniques, perforated and expanded metal, are particularly prized for their high strength, reliability, and flexibility, and their ability to provide high levels of security make them particularly beneficial for new or rehabbed buildings. Security Mesh inside Walls, Ceilings, and Floors

Security Mesh inside Walls, Ceilings, and Floors Making use of innovative new metal solutions allows for trade collaboration in the architectural industry. The large range of customization capabilities for perforated and expanded metals allows for a great deal of collaboration to take place between suppliers and clients. Because these metals can come in so many shapes, forms, and abilities, they offer limitless possibilities.

Making use of innovative new metal solutions allows for trade collaboration in the architectural industry. The large range of customization capabilities for perforated and expanded metals allows for a great deal of collaboration to take place between suppliers and clients. Because these metals can come in so many shapes, forms, and abilities, they offer limitless possibilities. An intermediate raw material, expanded metal allows light and air to flow freely through it while still serving as a rigid screen solution with a variety of open-area configuration options. It’s available in carbon steel, aluminum, copper, nickel, and several other alloys. With its

An intermediate raw material, expanded metal allows light and air to flow freely through it while still serving as a rigid screen solution with a variety of open-area configuration options. It’s available in carbon steel, aluminum, copper, nickel, and several other alloys. With its  Perforated metal

Perforated metal